9 月 . 19, 2024 00:29 Back to list

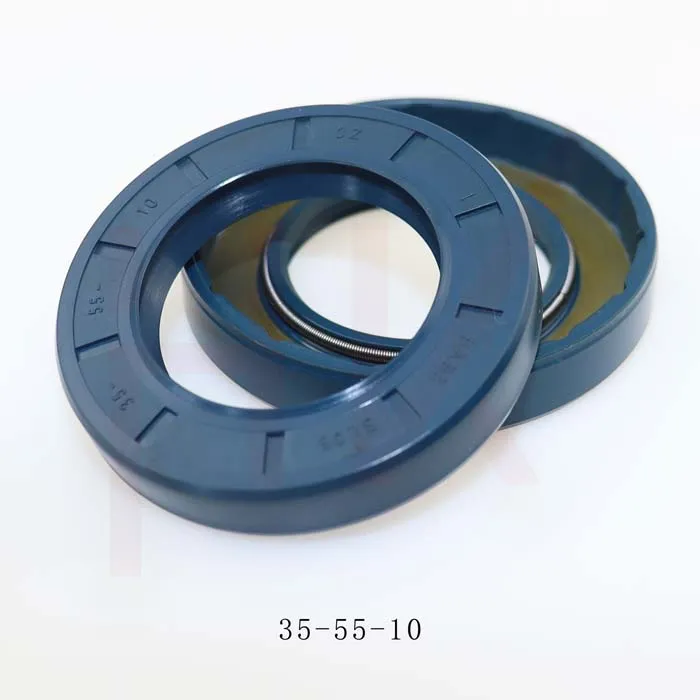

double lip wiper seal

Understanding the Double Lip Wiper Seal A Comprehensive Overview

The double lip wiper seal is a crucial component widely used in hydraulic and pneumatic systems. Designed to prevent the ingress of dirt, dust, and other contaminants while maintaining the necessary lubrication, this seal plays a significant role in enhancing the operational efficiency and longevity of machinery.

One of the primary advantages of the double lip wiper seal is its unique design, which features two sealing lips. This design provides superior resistance against contamination compared to single lip seals. The inner lip is designed to retain lubricant, while the outer lip acts as a barrier against external contaminants. This dual-action feature ensures that any harmful particles are kept away from critical moving parts, reducing the risk of wear and tear.

Materials used in the manufacturing of double lip wiper seals are typically chosen based on the specific application requirements. Common materials include rubber compounds, such as Nitrile, Viton, and Polyurethane. These materials are selected for their excellent elasticity, resilience, and ability to withstand various temperatures and pressures. The right material selection not only enhances the seal's performance but also contributes to the overall reliability of the equipment in which they are installed.

double lip wiper seal

Double lip wiper seals are particularly popular in applications involving heavy machinery, automotive systems, and industrial equipment. In hydraulic cylinders, for example, they prevent hydraulic fluid leakage and protect the internal components from external debris. This protection is vital for maintaining the efficiency of the hydraulic system and preventing costly repairs due to equipment failure.

The installation of double lip wiper seals is straightforward, yet it requires meticulous attention to detail. Proper alignment and lubrication during installation are critical to ensuring optimal performance and lifespan. Regular maintenance checks are also essential to identify any wear or degradation of the seals over time, allowing for timely replacements that can prevent more extensive damage to equipment.

In conclusion, the double lip wiper seal is an indispensable component that enhances the performance and reliability of various mechanical systems. Its ability to keep contaminants at bay while ensuring lubrication is vital for the optimal functioning of machinery. As industrial demands continue to evolve, the importance of such components will only increase, underscoring the need for ongoing innovation in seal technology.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories