2 月 . 18, 2025 06:49 Back to list

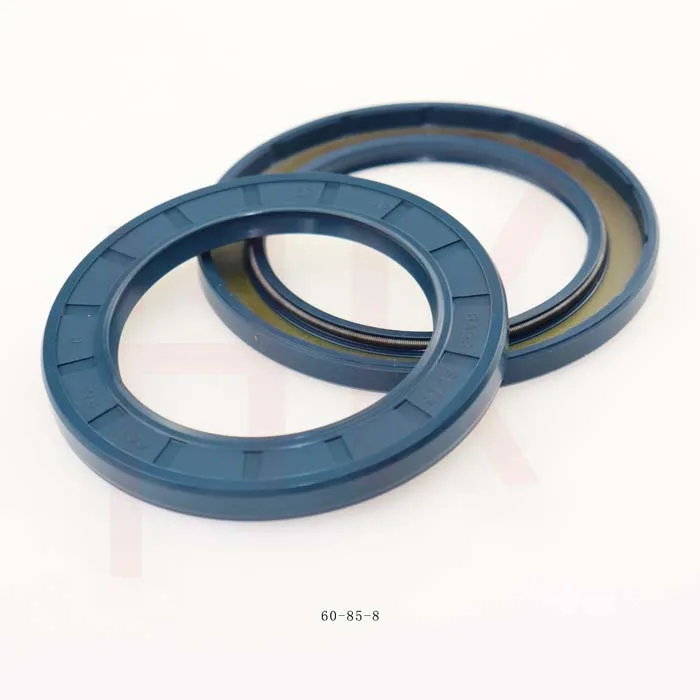

oil seal tcv

In terms of authoritativeness, cylinder seal kit manufacturers with decades of experience and a proven track record provide products that are recognized for their reliability and innovative solutions. These industry leaders invest heavily in research and development to introduce seal kits that can withstand extremely demanding conditions. Trust in these brands is built over years of consistently meeting and exceeding industry standards, making them the go-to resources for quality parts. Trustworthiness is paramount when selecting cylinder seal kits. It involves ensuring that the kits are sourced from reputable suppliers who offer genuine parts backed by warranties and support. The significance of sourcing from trustworthy vendors cannot be overstated, as counterfeit or substandard seal kits can lead to catastrophic system failures, incurring not only financial losses but also safety hazards. Trusted suppliers provide documentation and certification that guarantee the performance and resilience of their seal kits. In summary, cylinder seal kits are indispensable for maintaining the efficient operation of hydraulic systems across various industries. Through years of experience, deep technical expertise, and reliance on authoritative manufacturers, businesses can ensure they select seal kits that enhance the longevity and reliability of their equipment. Trust in suppliers further underscores the decision-making process, assuring that the products installed will meet the rigorous demands of today’s industrial applications. By prioritizing quality and expertise, one not only preserves their machinery but also secures peace of mind, knowing their systems are equipped with the best the industry has to offer.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories