1 月 . 23, 2025 02:42 Back to list

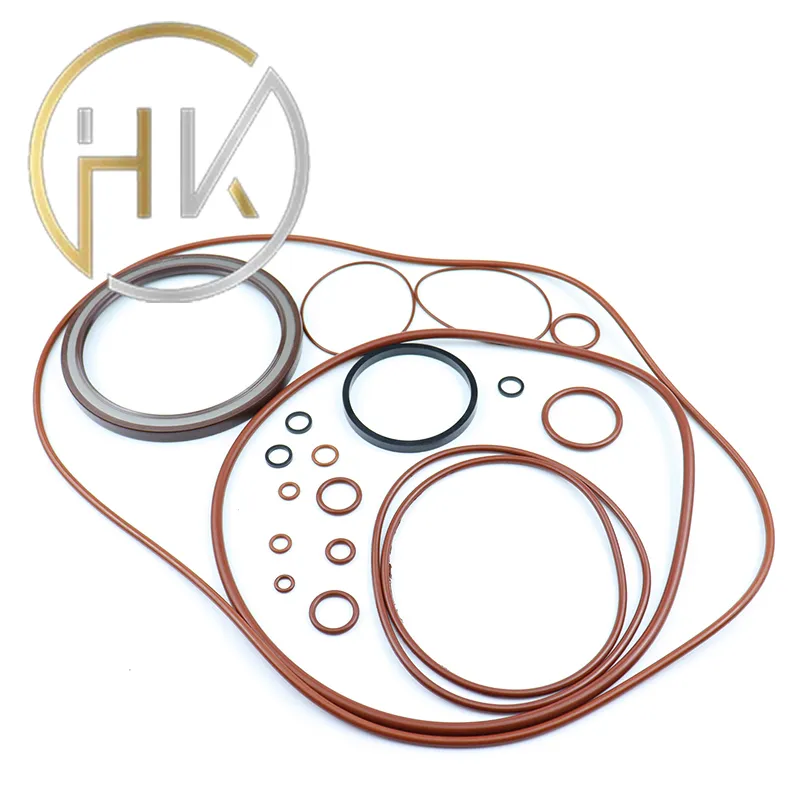

dkb seal

Moreover, investing in recognized brands with proven track records adds a layer of trustworthiness to purchases. Industry leaders continually refine their products, ensuring they meet or exceed industry standards. This commitment to quality guarantees that when businesses opt for superior seal kits, they are also opting for enhanced safety and efficiency. Testimonials, case studies, and expert reviews serve as excellent resources for validating product claims and performances, contributing to informed purchasing decisions. Incorporating cylinder seal kits as part of a broader maintenance strategy illustrates an organization’s commitment to expertise and operational excellence. Regular training for technical staff on the use and installation of these kits ensures that the benefits are fully realized. This proactive approach not only optimizes machinery performance but also extends the lifespan of equipment, thereby maximizing return on investment. Finally, the rise of digital platforms allows for easy access to a wealth of information about cylinder seal kits. Engaging with online communities, such as forums and discussion groups, provides insights from experienced professionals who share their real-world experiences. This collaborative knowledge exchange enables both seasoned professionals and newcomers to navigate the complexities of seal kit selection and application with greater confidence. In conclusion, cylinder seal kits play a pivotal role in the seamless functioning of machinery across various industries. Their selection requires careful consideration of materials, compatibility, and manufacturer credibility. By aligning purchases with expert guidelines and utilizing community knowledge, businesses can ensure they achieve reliability, enhance performance, and uphold safety standards—all crucial elements for sustained industrial success.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories