9 月 . 16, 2024 11:56 Back to list

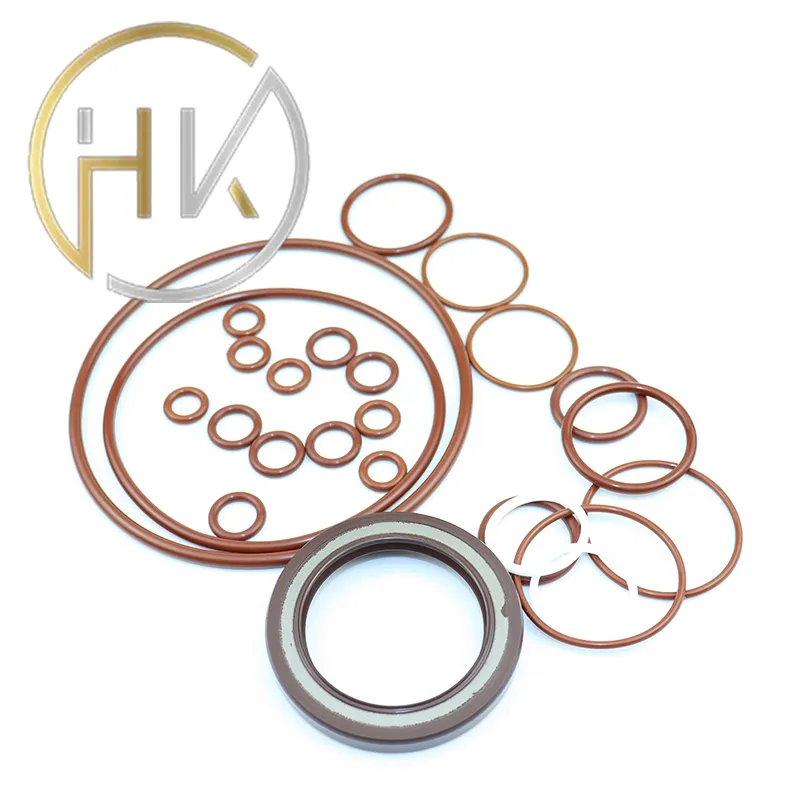

cylinder wiper seal

Understanding Cylinder Wiper Seals Function, Types, and Applications

Cylinder wiper seals are critical components in hydraulic and pneumatic systems, ensuring the efficient operation and longevity of the machinery they are used in. These seals play an indispensable role in preventing contaminants from entering the cylinder while simultaneously keeping the hydraulic fluid or pneumatic air from leaking out. As the name suggests, these seals are specifically designed for the wiper function, essentially wiping away debris and maintaining a clean environment around moving surfaces.

Function of Wiper Seals

The primary function of a cylinder wiper seal is to protect the piston rod from dirt, dust, and other particulate matter that can lead to wear and damage. This is particularly important in environments where contaminants are prevalent, such as construction sites, manufacturing plants, and outdoor equipment. By maintaining a clean surface, wiper seals help to ensure that the sealing elements (such as piston seals) have a longer service life, reducing maintenance costs and equipment downtime.

Wiper seals operate by creating a dynamic sealing effect as the piston rod moves in and out of the cylinder. They adopt a specific design that allows them to conform to the rod’s surface while providing sufficient contact to wipe away contaminants. This action is vital for preventing abrasive materials from scratching the rod or entering the cylinder, which could compromise the integrity of the entire system.

Types of Wiper Seals

cylinder wiper seal

There are various types of cylinder wiper seals, each tailored for different operating conditions and applications. The most common types include

1. U-Cup Wipers These seals feature a U-shaped cross-section and are ideal for low to medium-pressure applications. They are simple in design and easy to install. 2. V-Ring Wipers Made from rubber or other elastomers, V-ring seals provide excellent flexibility and are suitable for dynamic applications where movement is present. 3. Lip Seals These seals incorporate one or multiple lips to provide an enhanced sealing surface. They are effective in handling high pressures and offer robust performance in severe conditions.

4. Various Material Options Wiper seals can be manufactured from a range of materials, including polyurethane, rubber, and PTFE, allowing for compatibility with different fluids and operating temperatures.

Applications

Cylinder wiper seals find applications across a broad spectrum of industries, including automotive, aerospace, manufacturing, and agriculture. In hydraulic cylinders used in construction equipment, wiper seals play a vital role in ensuring the smooth and reliable operation of heavy machinery. Similarly, in pneumatic systems, these seals help maintain pressure and efficiency by keeping contaminants at bay.

In conclusion, understanding the importance of cylinder wiper seals is crucial for anyone engaged in industries reliant on hydraulic and pneumatic systems. Their ability to prolong equipment life and enhance operational efficiency makes them an indispensable asset. Regular inspection and maintenance of these seals can lead to significant cost savings and improved machinery reliability, underscoring their value in modern engineering applications.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories