10 月 . 22, 2024 08:02 Back to list

Bespoke Oil Seals for Customized Applications and Industrial Needs

The Importance of Custom Made Oil Seals in Industrial Applications

In the world of machinery and manufacturing, the role of oil seals cannot be overstated. These vital components not only prevent leaks of lubricants but also protect internal parts from contaminants such as dirt and moisture. While standard oil seals are readily available, custom made oil seals have emerged as a preferred solution for various industrial applications. This article dives into the significance of custom oil seals and their impact on operational efficiency.

What Are Custom Made Oil Seals?

Custom made oil seals are specifically designed to meet the unique requirements of a particular application. Unlike standard seals, which come in set sizes and materials, custom seals can be tailored in dimensions, materials, and shapes to accommodate the operational parameters of specific machinery. This bespoke manufacturing process ensures that the seals perform optimally within their designated environments, improving the overall performance of the equipment they are used in.

Benefits of Custom Made Oil Seals

1. Perfect Fit One of the primary advantages of custom oil seals is their ability to fit perfectly within the equipment’s design. Machinery can sometimes have unconventional shapes or sizes that standard seals cannot accommodate. With custom made solutions, users can ensure that every seal fits precisely, reducing the risk of leaks and inefficiencies.

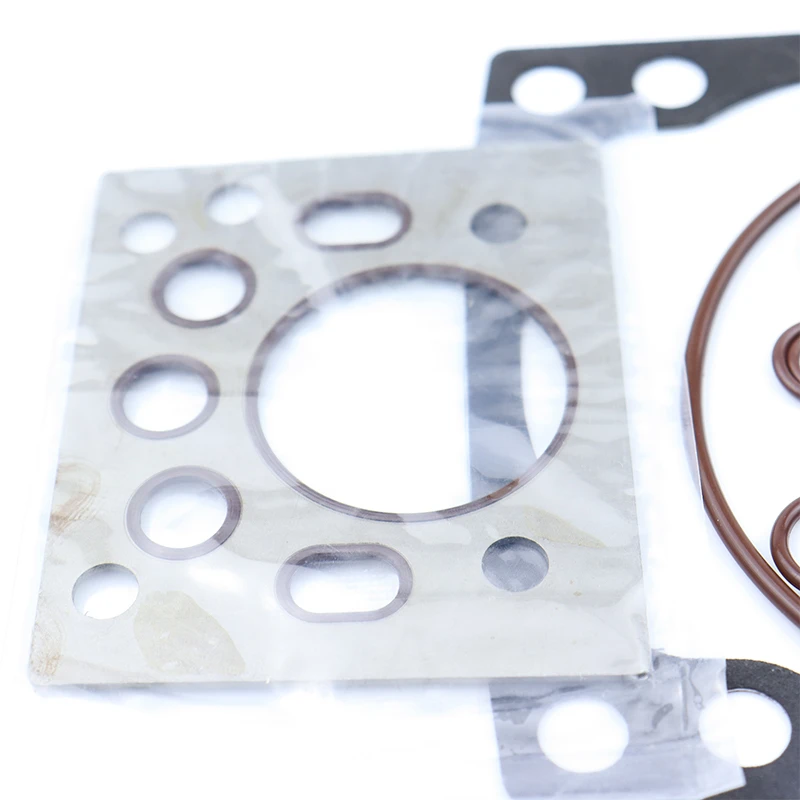

custom made oil seals

2. Material Selection Different environments require different materials. For example, high-temperature applications may necessitate seals made of specific elastomers or thermoplastics capable of withstanding extreme conditions without degrading. Custom oil seals allow for the selection of materials that best suit the operating environment, ensuring durability and longevity.

3. Enhanced Performance Custom seals are designed with the performance requirements of the specific application in mind. By considering factors like pressure, speed, and surrounding conditions, manufacturers can create seals that deliver superior sealing capabilities, ultimately leading to improved machine performance.

4. Cost-Effectiveness While some may view custom oil seals as a more expensive option upfront, they often prove to be cost-effective over time. A perfect fit reduces wear and tear on machinery parts, decreases the frequency of replacements, and minimizes downtime caused by leaks or maintenance. This long-term savings can significantly outweigh the initial costs associated with custom manufacturing.

5. Reduced Downtime In industrial settings, downtime can result in substantial financial losses. Custom oil seals can be designed to meet the exact specifications of older or specialized machinery that may no longer be in production. This capability means that businesses can maintain operations without the costly delays associated with sourcing non-standard parts.

Conclusion

Incorporating custom made oil seals into industrial applications can greatly enhance operational efficiency and reliability. Their ability to provide a precise fit, tailored material selection, and optimized performance makes them indispensable for businesses that rely on machinery to operate efficiently. While there may be an additional investment in acquiring custom seals, the long-term benefits—reduced downtime, increased productivity, and lower maintenance costs—are well worth the consideration. In today’s fast-paced industrial environment, where efficiency is key, businesses cannot afford to overlook the advantages offered by custom manufacturing solutions like oil seals. By making this intelligent investment, companies can ensure their equipment remains operational and reliable for years to come.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories