12 月 . 03, 2024 14:38 Back to list

Cross Cylinder Seal Kit for Enhanced Performance and Durability in Hydraulic Systems

Understanding Cross Cylinder Seal Kits Essential Components for Hydraulic Systems

Cross cylinder seal kits are integral components in various hydraulic systems, widely utilized in industrial machinery, automotive applications, and construction equipment. Ensuring the effective operation of hydraulic cylinders, these seal kits are crucial for preventing leaks, maintaining pressure, and ensuring the longevity of the machinery. This article explores the significance, components, and maintenance of cross cylinder seal kits in hydraulic systems.

What Are Cross Cylinder Seal Kits?

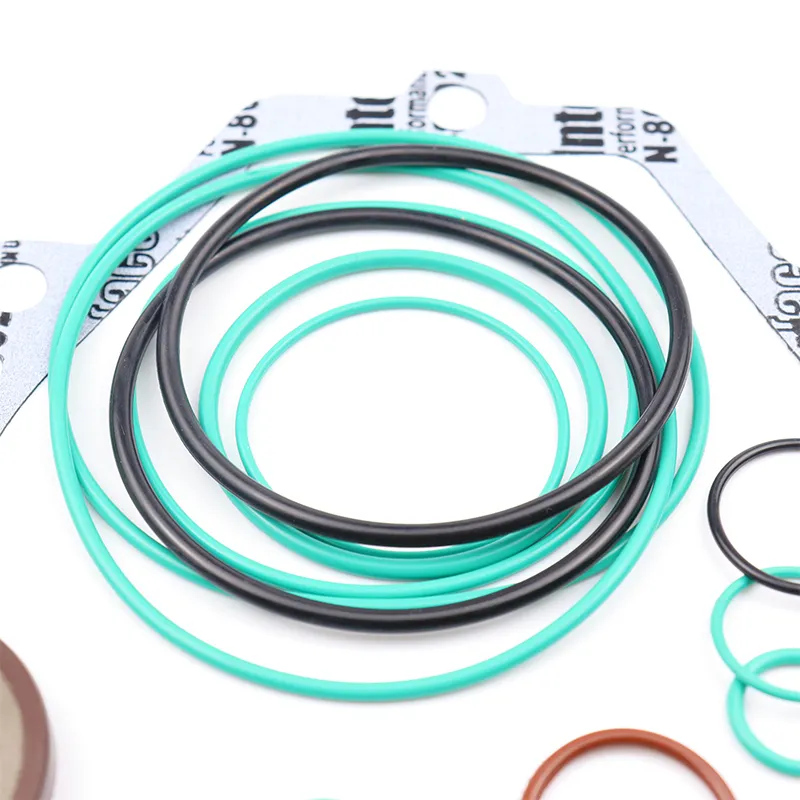

Cross cylinder seal kits are specifically designed to seal hydraulic cylinders that involve complex motion. Unlike standard cylinders, cross cylinders have a unique design that requires specialized sealing solutions to accommodate their specific operational needs. These kits typically contain various seals, O-rings, and backup rings made from materials such as nitrile rubber, polyurethane, or fluoropolymers, depending on the operating conditions of the hydraulic system.

Key Components

1. Seals The main components of any seal kit are the seals themselves, which prevent hydraulic fluid from leaking out of the cylinder. These seals come in several shapes, such as U-cups, piston seals, and rod seals, each designed to fit a specific part of the cylinder.

2. O-Rings O-rings are essential for providing a secondary seal to the main seal, enhancing leak prevention. They are versatile and can be found throughout the hydraulic system, securing connections between various components.

3. Backup Rings Designed to reinforce seals, backup rings prevent the seals from extruding in high-pressure environments, ensuring that the seals function optimally under intense operational conditions.

4. Guide Rings While not present in every seal kit, guide rings help maintain alignment within the hydraulic cylinder, reducing wear and tear on seals during operation.

cross cylinder seal kit

Importance of Quality

The quality of the seals used in cross cylinder seal kits directly impacts the performance and reliability of hydraulic systems. High-quality materials resist wear, temperature fluctuations, and chemical exposure, offering better durability compared to inferior alternatives. Superior seals help minimize downtime between repairs and replacements, contributing to increased productivity and efficiency in operations.

Installation and Maintenance

Proper installation of cross cylinder seal kits is vital to their function. Following manufacturer guidelines is critical, as improper installation can lead to early failure of seals, resulting in leaks and operational inefficiencies. Regular maintenance checks are also essential to identify wear and replace seals proactively. This preventive approach can save significant costs and prevent unexpected breakdowns that could halt operations.

Signs of Wear and Failure

Understanding the signs of seal wear is crucial for effective maintenance. Common indicators include

- Fluid Leaks Visible leaks around the seals indicate a failure that necessitates immediate attention. - Inconsistent Performance If the hydraulic cylinder operates erratically or shows a decrease in power, worn seals might be the cause. - Unusual Noises Grinding or squeaking noises during operation might signal misalignment or wear of the seals.

Conclusion

Cross cylinder seal kits are fundamental to the efficient operation of hydraulic systems across various industries. By understanding their components, significance, and maintenance requirements, operators can ensure optimal performance and longevity of their machinery. Investing in high-quality seal kits and adhering to proper installation and maintenance procedures not only enhances the reliability of hydraulic systems but also significantly reduces operational downtime and costs. Whether in construction, manufacturing, or automotive applications, the importance of maintaining cross cylinder seal kits should not be underestimated. With regular checks and timely replacements, machinery can operate smoothly, ensuring productivity and efficiency in all operations.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories