8 月 . 15, 2024 06:50 Back to list

Comprehensive Guide to Choosing the Right Motor Seal Kit for Your Vehicle Maintenance Needs

Understanding Motor Seal Kits Essential Components for Maintenance

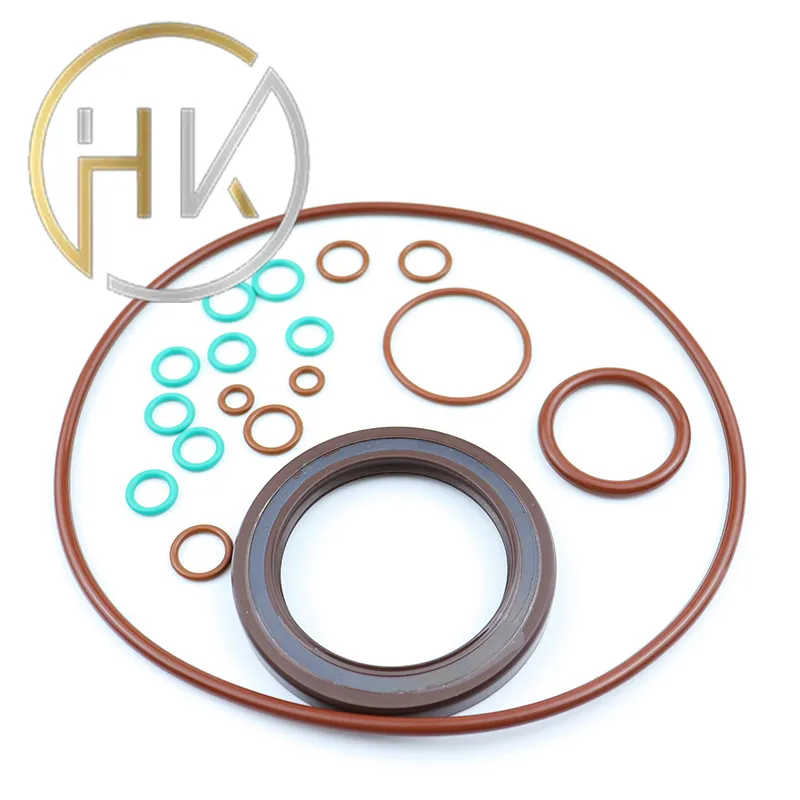

Motor seal kits are essential components in the maintenance and repair of various types of machinery, especially those involving motors and hydraulic systems. These kits typically contain a selection of seals and gaskets specifically designed to prevent leaks, protect internal components, and ensure the proper functioning of equipment. This article explores the importance of motor seal kits, their components, and considerations for choosing the right kit for your needs.

Importance of Motor Seal Kits

Motor seal kits are crucial for several reasons. Primarily, they help maintain the integrity of a motor or hydraulic system by preventing fluid leaks. In many applications, such as automotive or industrial machinery, even a small leak can lead to significant operating issues. Leaks can result in decreased efficiency, increased wear and tear, and, ultimately, costly repairs or replacements.

Another critical aspect is that seals play a vital role in keeping contaminants such as dust, dirt, and moisture out of sensitive areas of machinery. When these contaminants enter, they can cause corrosion, damage, and premature failure of components. By utilizing the right seals from a motor seal kit, operators can prolong the lifespan of their equipment and reduce maintenance costs over time.

Components of Motor Seal Kits

A typical motor seal kit can consist of various components, including

1. O-Rings These are circular seals that are commonly used in machinery to prevent leaks at joints where two parts come together. They are made from various materials to suit different applications, including rubber, silicone, and fluorocarbon.

2. Gaskets Gaskets create a seal between two surfaces, preventing the passage of fluids or gases. They come in many shapes and materials, including paper, rubber, cork, and metal, providing versatility based on temperature and pressure requirements.

3. Shaft Seals Also known as oil seals, these are used to seal moving parts within a motor, preventing leakage around shafts. They are critical in applications where lubricants are used to reduce friction.

motor seal kit

4. Lip Seals These seals are designed to provide better protection against contamination and are often used in harsh environments. The lip acts as a barrier, keeping out contaminants while maintaining lubricant retention.

5. Backup Rings Used in conjunction with O-rings, backup rings are designed to prevent extrusion and improve sealing performance in high-pressure applications.

Choosing the Right Motor Seal Kit

Selecting the appropriate motor seal kit involves several considerations

- Compatibility It is essential to ensure that the seals in the kit are compatible with the specific motor or machinery in use. This includes checking the size, shape, and material of the seals.

- Application Environment The operating conditions, such as temperature, pressure, and exposure to chemicals, play a significant role in determining the right materials for seals. For example, a high-temperature environment may require silicone seals, while oil-resistant materials are necessary for hydraulic applications.

- Quality and Standards Always choose kits from reputable manufacturers that adhere to industry standards. Quality seals will ensure better performance and longevity, reducing the likelihood of leaks.

- Cost-Effectiveness While it may be tempting to opt for cheaper alternatives, investing in quality motor seal kits can prevent costly repairs and downtime caused by leaks and equipment failure.

Conclusion

Motor seal kits are invaluable for maintaining the efficiency and reliability of motors and hydraulic systems. By understanding their importance and components, and making informed choices, operators can significantly enhance their machinery's performance and lifespan. Regular maintenance and timely replacement of seals will not only protect investments but also ensure smooth and trouble-free operation.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories