2 月 . 19, 2025 10:02 Back to list

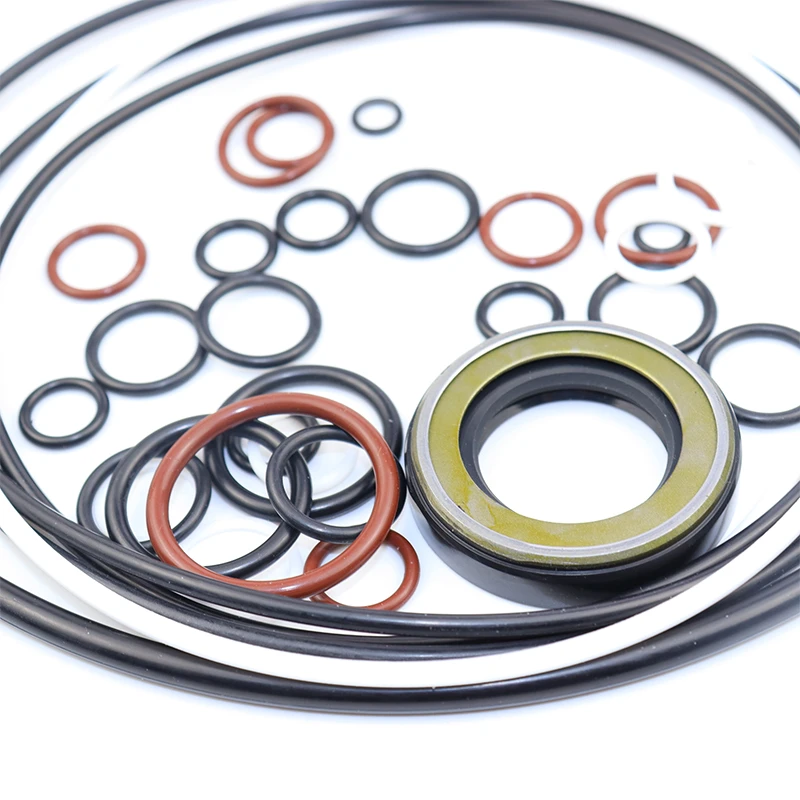

Standard High Pressure TCV Type Hydraulic Oil Seal

From an authoritativeness standpoint, sourcing seal kits from reputable manufacturers or suppliers who adhere to industry standards is non-negotiable. Companies with ISO certification offer an added assurance of quality control processes. These manufacturers back their products with detailed technical support, ensuring that the end-user is not left guessing about compatibility or installation processes. Trust in a seal kit also comes from real-world feedback. Operators and maintenance teams often share insights and reviews about specific seal kits based on their performance in challenging conditions. These reviews provide invaluable insights that go beyond marketing claims, highlighting which products consistently deliver reliability and value. Moreover, building trust involves understanding that even the best seal kits are not immune to environmental factors. Proper system design—and by extension, seal choice—must account for potential chemical exposure, abrasive contaminants, and temperature fluctuations. Consulting comprehensive guides provided by manufacturers can ensure that the selected seal kit matches the predicted environment. Finally, sustainability and efficiency are increasingly crucial in the selection process. Many industries are shifting towards eco-friendly options, prompting manufacturers to innovate with biodegradable materials without compromising performance. An effective chief hydraulic cylinder seal kit supports not just machinery longevity but also aligns with broader ecological goals. In conclusion, the choice of a chief hydraulic cylinder seal kit reflects a blend of experience, deep-seated expertise, authoritative sourcing, and unwavering trustworthiness. Whether you are maintaining agricultural equipment or deploying hydraulic systems in complex manufacturing settings, selecting the right seal kit ensures sustained operational efficiency and minimal downtimes, embodying a commitment to excellence in hydraulic machinery maintenance.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories