2 月 . 12, 2025 19:18 Back to list

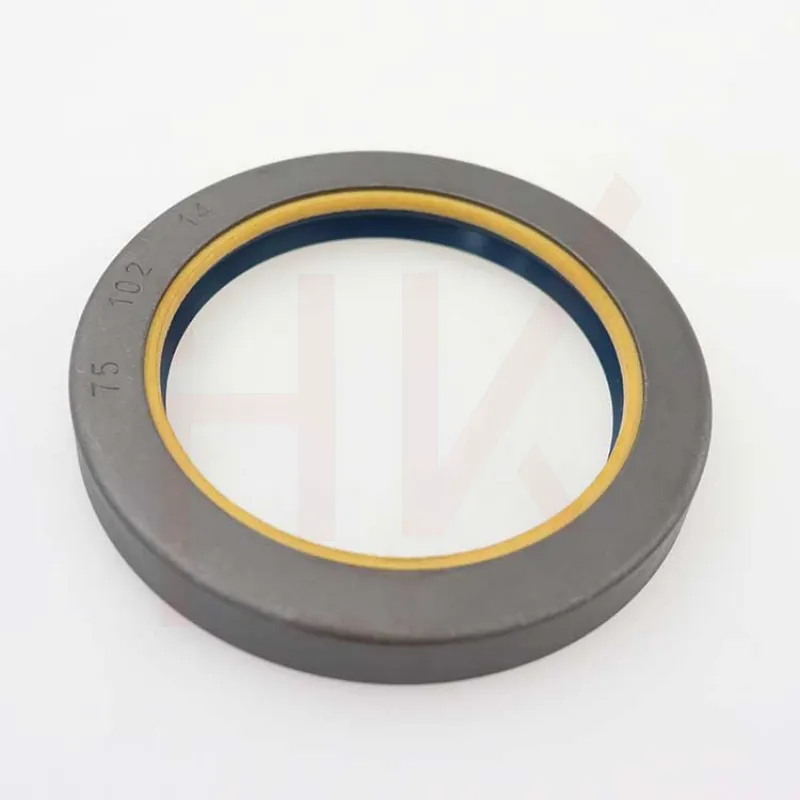

boom cylinder seal kit

Building authority in the realm of hydraulic systems extends beyond mere technical knowledge. It involves cultivating relationships with trusted manufacturers and suppliers who offer genuine, high-quality seal kits. These partnerships are crucial for accessing products that meet rigorous industrial standards and performance criteria. An authoritative voice in this industry emphasizes the importance of adhering to manufacturers' guidelines, ensuring that the seal kits are compatible with specific machinery models and applications. Trustworthiness in discussing and recommending boom cylinder seal kits is earned through transparency and a proven track record of successful installations and maintenance. It emphasizes clear communication with clients, ensuring they understand the critical role of seal kits and the impact of their choices on operational efficiency and cost management. Trust is further solidified by providing detailed documentation and insights into seal performance, life expectancy, and maintenance best practices. Practical experience is the backbone of delivering not just effective solutions but also reassuring clients of a commitment to quality and reliability. From assessing equipment needs to implementing tailored maintenance plans, a client-centric approach underscores the value of trust in every professional relationship formed in this industry. In conclusion, the boom cylinder seal kit is not just a component but a pivotal factor in ensuring the performance and durability of hydraulic systems. Mastery of this element combines experience with professional knowledge and authoritative insights, ensuring trustworthy guidance in selecting and maintaining these vital parts. My commitment as an expert in the field is to deliver not only technical proficiency but also a robust understanding of modern seal technology and a dedication to client satisfaction.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories