12 月 . 03, 2024 18:51 Back to list

boom cylinder seal kit

Understanding Boom Cylinder Seal Kits A Comprehensive Guide

In the world of hydraulic machinery, the importance of efficient function and maintenance cannot be overstated. Among the various components that ensure the smooth operation of hydraulic systems, the boom cylinder seal kit plays a crucial role. This article delves into the significance, composition, installation, and maintenance of boom cylinder seal kits, aiming to provide a comprehensive understanding for operators and maintenance personnel.

What is a Boom Cylinder Seal Kit?

A boom cylinder seal kit is a collection of seals and components designed to prevent hydraulic fluid from leaking out of the boom cylinder in equipment such as excavators, cranes, and other heavy machinery. These seals are critical in maintaining the pressure necessary for the hydraulic system to function effectively. Without appropriate sealing, hydraulic fluid can escape, leading to inefficient operation, potential damage to machinery, and costly repairs.

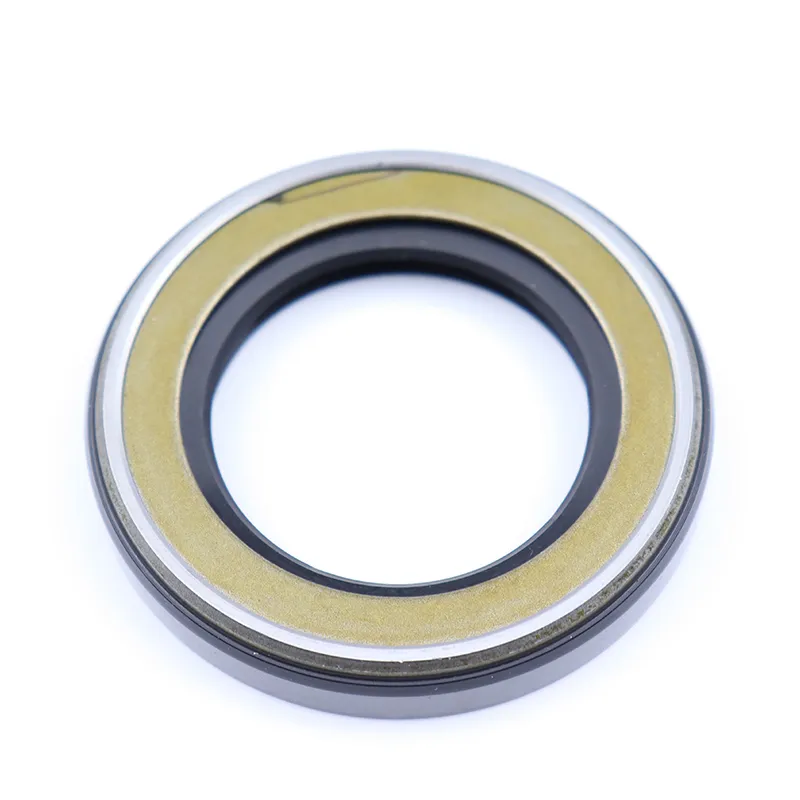

Components of a Seal Kit

Typically, a boom cylinder seal kit includes several types of seals, such as O-rings, backup rings, wiper seals, and rod seals. Each component serves a specific function

1. O-Rings These circular seals fit snugly into grooves and serve as the primary barrier against fluid leakage. 2. Backup Rings Used in conjunction with O-rings, backup rings prevent extrusion and enhance the sealing pressure under high hydraulic loads.

3. Wiper Seals Positioned at the outer end of the cylinder, wiper seals keep contaminants such as dirt and debris from entering the hydraulic system.

Each kit is designed to meet the specifications of different machinery, and selecting the right kit is imperative for optimal functionality.

Importance of Regular Maintenance

boom cylinder seal kit

Regular maintenance of boom cylinder seal kits is essential for maximizing the lifespan and performance of hydraulic machinery. Over time, seals can wear out due to exposure to extreme temperatures, high pressures, and abrasive materials. A worn seal can lead to hydraulic fluid leakage, resulting in a drop in system pressure, reduced operational efficiency, and potential breakdowns.

Installation Process

Proper installation of a boom cylinder seal kit is crucial for ensuring the longevity and functionality of the hydraulic system. Here are the steps generally involved in the installation process

1. Disassemble the Cylinder Start by carefully disassembling the boom cylinder while taking note of the arrangement of the seals.

2. Clean the Components Remove any old seals and thoroughly clean the cylinder and piston rod to eliminate dirt and debris.

3. Install New Seals Begin by placing the wiper seal, followed by the rod seal, and finally, the O-rings and backup rings. Make sure each seal fits correctly into its designated groove without pinching.

4. Reassemble the Cylinder Once all seals are installed, reassemble the cylinder carefully, ensuring that no seals are damaged in the process.

5. Test for Leaks After reassembly, conduct a pressure test to ensure that there are no leaks and that the system functions correctly.

Conclusion

The boom cylinder seal kit is a vital component in the maintenance of hydraulic systems in heavy machinery. Understanding its function, the significance of its components, and the processes involved in installation and maintenance can save operators time and money by preventing costly repairs and ensuring the machinery operates at peak efficiency. Regular inspection and prompt replacement of seals will contribute to a more sustainable operation, minimizing downtime and enhancing productivity in various industrial settings. With this knowledge, operators can take proactive measures to keep their hydraulic systems running smoothly, ensuring long-term reliability and performance.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories