2 月 . 11, 2025 00:11 Back to list

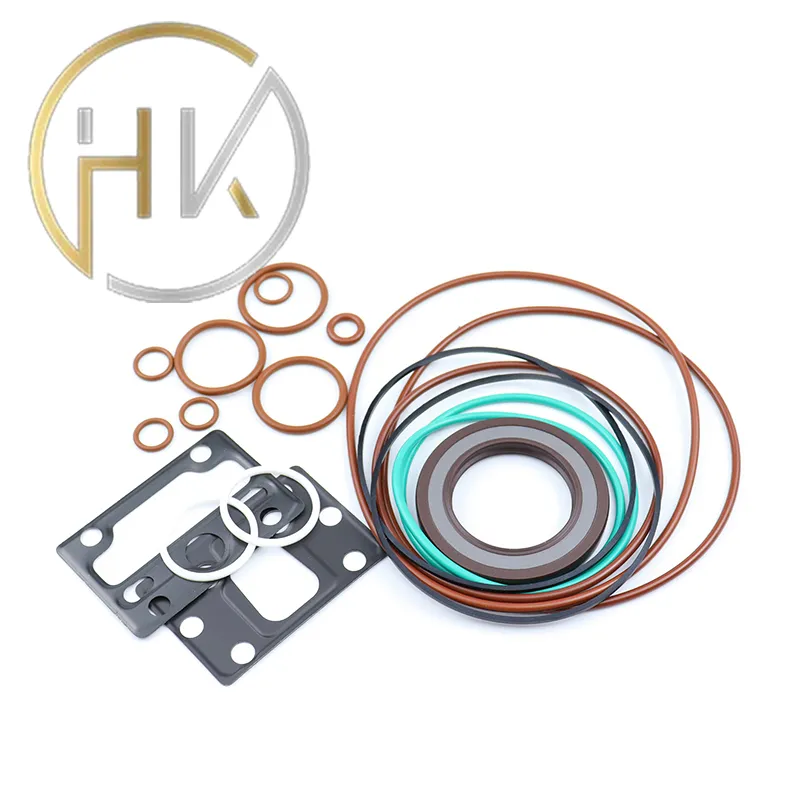

oil seal tcv

From a professional standpoint, the authority on bearing dust seals can only be asserted through continued research and adaptation to emerging technologies. Industry experts regularly conduct field tests and case studies to gauge the effectiveness of dust seal innovations. This ongoing commitment to research not only advances the field but also instills confidence in consumers that these experts are providing the most reliable and advanced solutions available. Trustworthiness in the context of bearing dust seals is fostered through transparency in communication and a consistent track record of delivering quality products. Manufacturers and suppliers who offer extensive warranties, detailed product documentation, and responsive customer support reinforce their credibility. Feedback mechanisms such as customer reviews and issue resolution processes also play a pivotal role in building and maintaining trust in the industry. In conclusion, bearing dust seals may seem like minor components within a larger system, yet their impact on performance and reliability cannot be overstated. Professionals in the field must leverage their expertise to innovate and optimize seal designs continually. This not only enhances operational efficiency but also extends the service life of critical machinery components. By embedding authority and trustworthiness in their practice, engineers and manufacturers ensure that their contributions to bearing dust seal technology remain invaluable to their clients and the industry at large.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories