2 月 . 19, 2025 08:30 Back to list

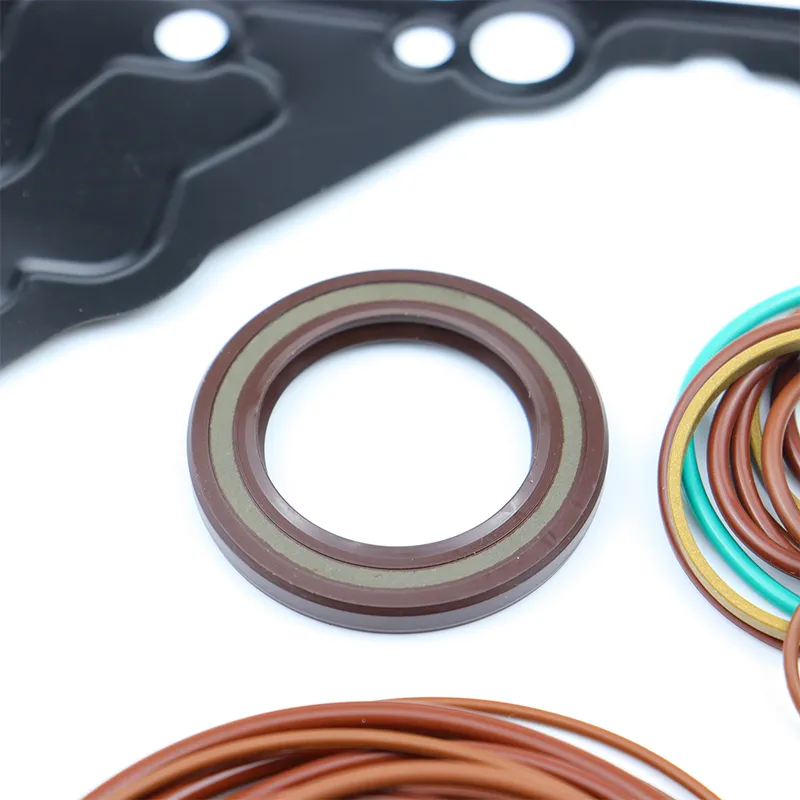

Standard High Pressure TCV Type Hydraulic Oil Seal

Advancements in technology have led to the development of innovative materials and designs that further boost the performance of cylinder seal kits. Modern designs may feature enhanced sealing geometries and advanced materials that offer superior resistance to heat, pressure, and environmental conditions. Staying updated with these advancements can significantly improve operational efficiency and reliability. Authoritativeness in the field comes with understanding the broader aspects of hydraulic systems. A malfunctioning seal can often be a symptom of larger issues within the hydraulic system. Regularly monitoring hydraulic fluid levels, checking for contamination, and ensuring system pressure settings comply with manufacturer guidelines are crucial practices recommended by experts. Building trust with suppliers is equally important. Source seal kits from reputable suppliers who provide warranties and have a proven track record of quality and reliability. Authentic products come with assurances that generic alternatives might not offer. Engaging with a trusted supplier also provides access to technical support and advice, which is invaluable when troubleshooting complex issues. The role of backhoe operators in maintaining seal integrity cannot be overstated. Operators should be trained to notice early signs of seal failure, such as fluid leaks, decreased lifting capacity, and abnormal noises. Encouraging operators to promptly report such issues is a practice that underscores the importance of experiential knowledge and contributes to the overall reliability and efficiency of backhoe operations. In conclusion, backhoe cylinder seal kits are critical to the performance and maintenance of backhoes. Through comprehensive understanding, expert installation, regular maintenance, and leveraging technological advancements, one can significantly enhance backhoe reliability and efficiency. Building authoritative knowledge, ensuring trustworthiness in supplier relationships, and empowering operators with the know-how to identify potential issues form the bedrock of an optimized backhoe operation strategy. With these practices in place, businesses can ensure sustained performance and minimize downtime, reflecting both expertise and reliability in the field.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories