12 月 . 03, 2024 16:58 Back to list

backhoe cylinder seal kits

Understanding Backhoe Cylinder Seal Kits

Backhoes are versatile pieces of machinery used in construction, landscaping, and various other industries. These machines combine the functions of a digger and a loader, allowing operators to perform a variety of tasks efficiently. However, like any heavy machinery, backhoes require regular maintenance to operate effectively. One critical aspect of their maintenance involves the hydraulic system, and specifically, the cylinder seals. This article will explore backhoe cylinder seal kits, their importance, composition, and maintenance considerations.

What is a Backhoe Cylinder Seal Kit?

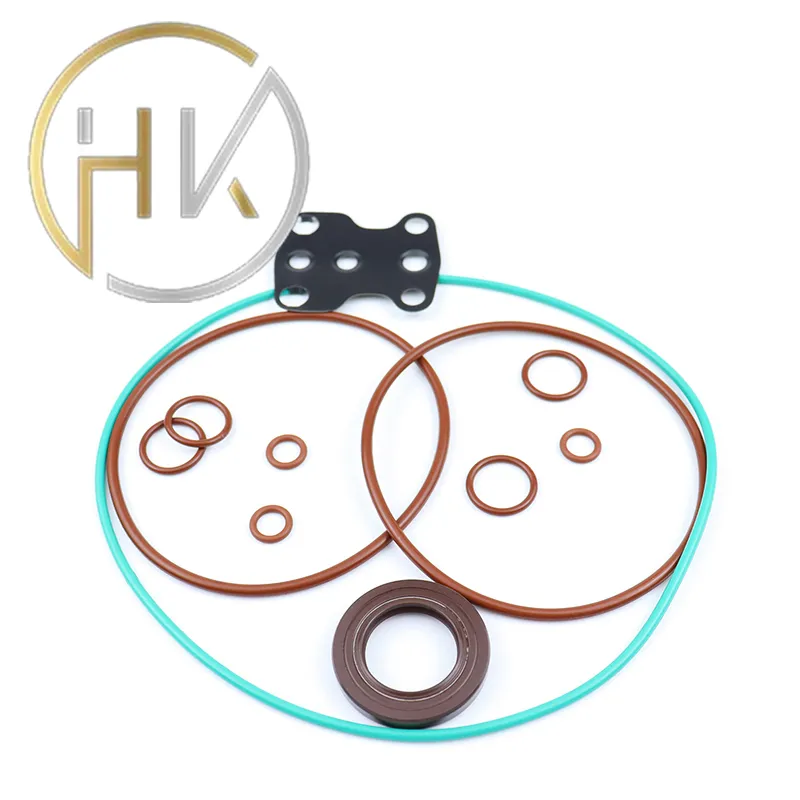

A backhoe cylinder seal kit comprises all the necessary seals, O-rings, and other components required to maintain the hydraulic cylinders of a backhoe. These seals are vital for preventing hydraulic fluid leaks, which can lead to inefficiencies, reduced performance, and potential damage to the machine. Properly functioning seals ensure that the hydraulic system maintains the pressure needed to operate the backhoe's bucket and arm effectively.

Importance of Cylinder Seals

The hydraulic system of a backhoe operates under high pressure, which is essential for lifting and digging. The cylinder seals play a pivotal role in maintaining this pressure by ensuring that hydraulic fluid does not escape the system. Over time, seals can wear out due to friction, exposure to extreme temperatures, and the corrosive nature of hydraulic fluids. Worn or damaged seals can result in hydraulic fluid leaks, leading to decreased performance and increased operational costs.

Moreover, replacing cylinder seals regularly as part of maintenance can prolong the life of the hydraulic system and the backhoe itself. This not only saves on repair costs but also minimizes downtime, allowing for more efficient work cycles.

Components of a Seal Kit

A typical backhoe cylinder seal kit includes various components designed to fit specific models and ensure optimal performance

. The primary components include1. Dynamic Seals These seals are used within the hydraulic cylinders and are designed to withstand the pressure and movement associated with the machine's operation.

2. Static Seals Unlike dynamic seals, static seals are not subject to movement. They are found at points where two stationary components meet, helping to prevent leakage at these junctions.

3. O-Rings These are circular seals that provide a secure seal at various joints within the hydraulic system. They are essential for preventing leaks at critical connection points.

backhoe cylinder seal kits

4. Backup Rings Used alongside O-rings, backup rings help to prevent extrusion of the O-rings under high pressure, ensuring a longer lifespan for the seals.

5. Wipers and Scrapers These components are designed to prevent dirt and debris from entering the cylinder, which could cause wear and tear on internal parts.

Maintenance Considerations

Proper maintenance of backhoe cylinder seals is crucial for ensuring the longevity and efficiency of the machine. Here are some tips to maintain these seals

1. Regular Inspections Periodically inspect the hydraulic system for any signs of leaks or wear. Early detection can prevent costly repairs and extended downtime.

2. Clean Hydraulic Components Always clean hydraulic components before reassembling them to prevent dirt and debris from contaminating the system.

3. Use Quality Fluids Ensure that the hydraulic fluid used in the system meets the specifications recommended by the manufacturer. Using the wrong fluid can accelerate wear on the seals.

4. Replace Seals Promptly If wear or damage is detected, replace the seals as soon as possible to avoid further complications.

5. Follow Manufacturer Guidelines Always refer to the manufacturer’s maintenance schedule and procedures for any specific recommendations regarding seal replacement and hydraulic system upkeep.

Conclusion

In conclusion, backhoe cylinder seal kits are essential components for the smooth operation of hydraulic systems in backhoes. Understanding their importance, components, and maintenance practices can significantly enhance the efficiency and lifespan of the equipment. Regular inspections and timely replacements of seals not only ensure optimal performance but also contribute to the overall health of the backhoe, safeguarding against costly repairs and minimizing downtime. The investment in quality seal kits and diligent maintenance ultimately pays off in the long run, allowing operators to focus on the task at hand with confidence.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories