2 月 . 07, 2025 01:38 Back to list

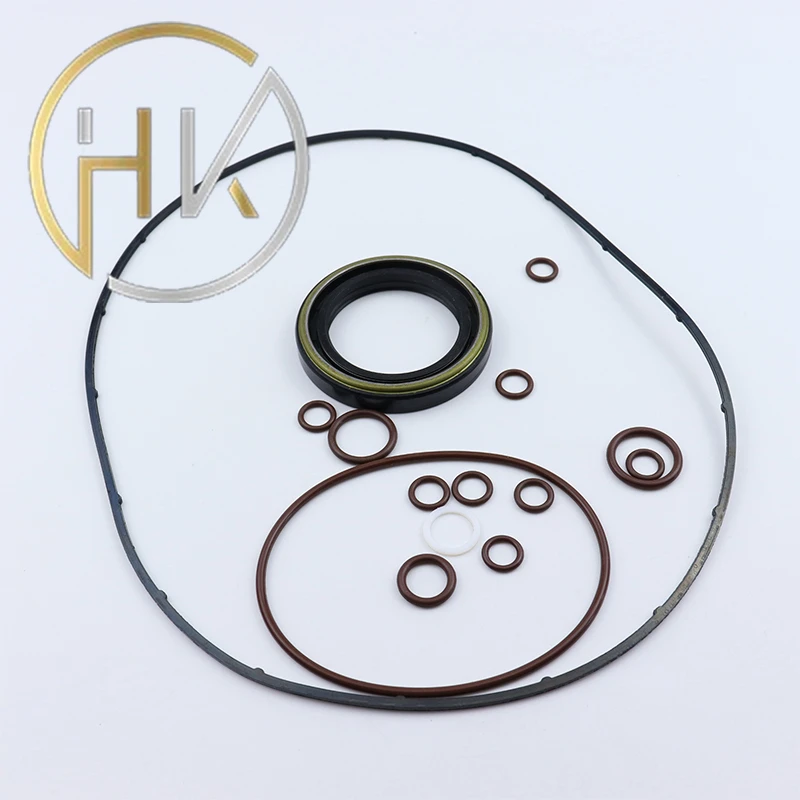

70 90 10 oil seal

Authoritatively trusted across industries, the 70 90 10 oil seal finds applications in a multitude of sectors ranging from automotive to agricultural machinery. In the automotive industry, these seals are crucial in car engines and transmissions, ensuring that the vehicle runs efficiently without oil leaks. Agricultural machinery relies heavily on these seals to keep debris and dust out of critical components, ensuring that the machinery can withstand tough environmental conditions. Additionally, in manufacturing sectors, they are employed in different types of pumps and compressors, playing a role in maintaining the efficiency and longevity of machinery. When considering the trustworthiness of any component in machinery, consistent performance and durability are vital. The 70 90 10 oil seal has proven itself reliable across countless applications, thanks to rigorous testing and adherence to industry standards. Factors such as the seal lip design, spring-loaded components, and quality materials contribute to a sealing solution that remains steadfast under pressure. Advanced manufacturing processes allow for precision in every seal, creating a product that delivers consistent performance over its lifespan. For those in need of replacement seals, identifying the right 70 90 10 oil seal involves assessing specific application conditions, including rotational speed, pressure, temperature, and fluid type. Consulting with experts and authoritative manufacturers in the field can ensure that the right seal is chosen for each unique scenario, enhancing machine reliability and minimizing unexpected downtimes. In summary, the 70 90 10 oil seal stands out as a key component in ensuring efficient operations across a wide range of machinery and vehicles. Its design showcases the expertise of engineers who have perfected the art of sealing over decades. Its widespread use across diverse industries underscores its authoritative reliability, and its consistent performance fosters trust among engineers and mechanics alike. As machines become more sophisticated, the importance of quality components like the 70 90 10 oil seal cannot be overstated, making it an indispensable asset in any maintenance toolkit. For businesses and operators looking to optimize their equipment's lifespan and reduce maintenance costs, investing in high-quality 70 90 10 oil seals is a decision grounded in expertise, authority, and trust.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories