2 月 . 12, 2025 12:22 Back to list

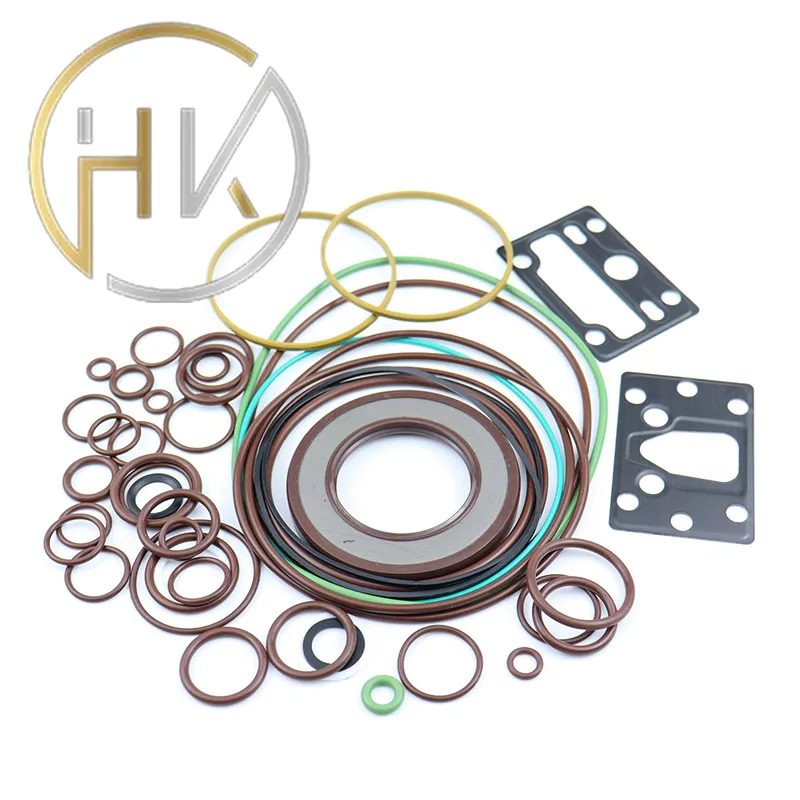

Standard High Pressure TCV Type Hydraulic Oil Seal

Furthermore, the customization of seal kits is an aspect that embodies modern advancements in hydraulic technology. For those dealing with bespoke machinery or non-standard systems, custom seal kits offer tailored solutions. These kits ensure compatibility and enhance efficiency, offering the flexibility needed in specialized applications. Engaging with reputable suppliers can facilitate access to high-quality custom solutions, adapted to unique operational demands. The industry’s trustworthiness and authority heavily rely on the quality assurance that accompanies these seal kits. Opt for suppliers renowned for their manufacturing standards and those who adhere to industry certifications. This guarantees that the seal kits will perform under pressure and meet the rigorous demands of diverse applications. Verifying the reputation of the supplier can be done through industry reviews, customer testimonials, and historical performance data. Educational resources, such as workshops and training seminars hosted by industry leaders, are invaluable for those seeking to deepen expertise. Engaging with these platforms enables operators to stay abreast of technological advances and repair methodologies. Likewise, industry forums and online communities offer practical insights drawn from real-world experiences, facilitating a deeper understanding of hydraulic systems. For those new to the field, partnering with knowledgeable professionals or consultants can bolster implementation strategies, ensuring systems are operating at peak performance. This partnership can also provide troubleshooting insights, capable of promptly resolving potential issues. The 5 inch hydraulic cylinder seal kit is an indispensable asset in maintaining system efficiency and reliability. By leveraging expert insights and adhering to best practices in selection, installation, and maintenance, operators can ensure their hydraulic systems remain robust and efficient, effectively minimizing downtime and extending equipment life. This strategic approach not only underscores industry authority but also fosters a trustworthy operational environment.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories