1 月 . 17, 2025 05:22 Back to list

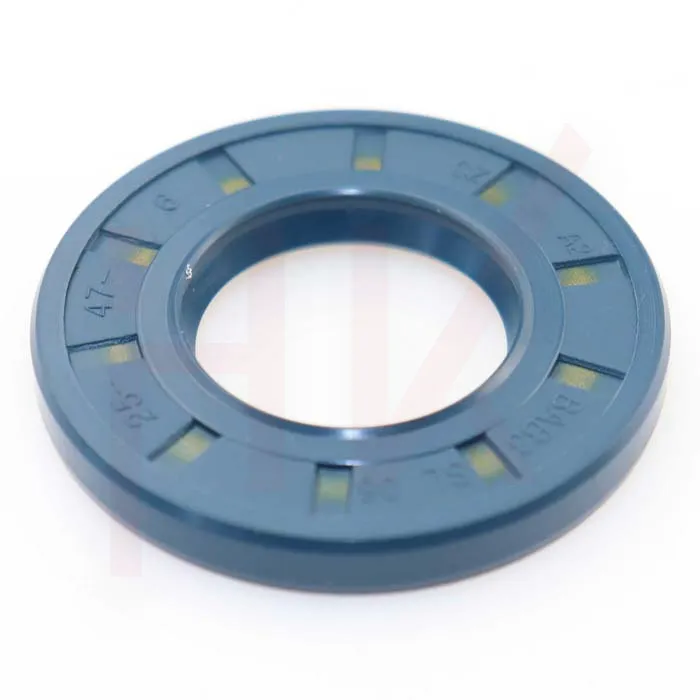

Standard High Pressure TCV Type Hydraulic Oil Seal

Professionals endorse integrating seals like the 55 80 10 in environments where precision and reliability are non-negotiable. Applications in automotive engines, gearboxes, and agricultural machinery frequently benefit from these seals, given their design's capability to endure rigorous conditions. In an automotive engine, for instance, oil seals are essential in maintaining engine oil intact within the engine’s sump while also facilitating the proper lubrication of critical components. In terms of authoritativeness, manufacturers of the 55 80 10 oil seal often adhere to the highest quality standards to ensure performance consistency. Firms with ISO 9001 certification, for example, underscore their commitment to quality and reliability in production processes, offering added assurance to buyers about the product’s credibility. Moreover, companies investing in research and development continuously refine these seals for enhanced resilience and lifespan, thus contributing to the seal’s authoritative standing in the market. Trustworthiness in using the 55 80 10 oil seal also extends to its proven track record across various sectors. Positive testimonials from industrial engineers, mechanics, and end-users underscore the seal’s ability to meet or exceed expectations under different operational stresses. Brands that are transparent about their testing methodologies and certification processes further augment their trust factor among consumers seeking reliable sealing solutions. In conclusion, the 55 80 10 oil seal represents a blend of precise engineering, material excellence, and application versatility, making it an invaluable component in numerous machinery contexts. For entities aiming to maintain peak operational efficiency, reduce maintenance downtime, and ensure machinery longevity, integrating a meticulously chosen oil seal like the 55 80 10 is indispensable. Its design and material composition not only meet the demanding requirements of various industries but also evoke confidence from those who prioritize performance and reliability in their operational undertakings.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories