9 月 . 25, 2024 18:40 Back to list

50x65x8 oil seal

Understanding the Importance of the 50x65x8 Oil Seal in Mechanical Applications

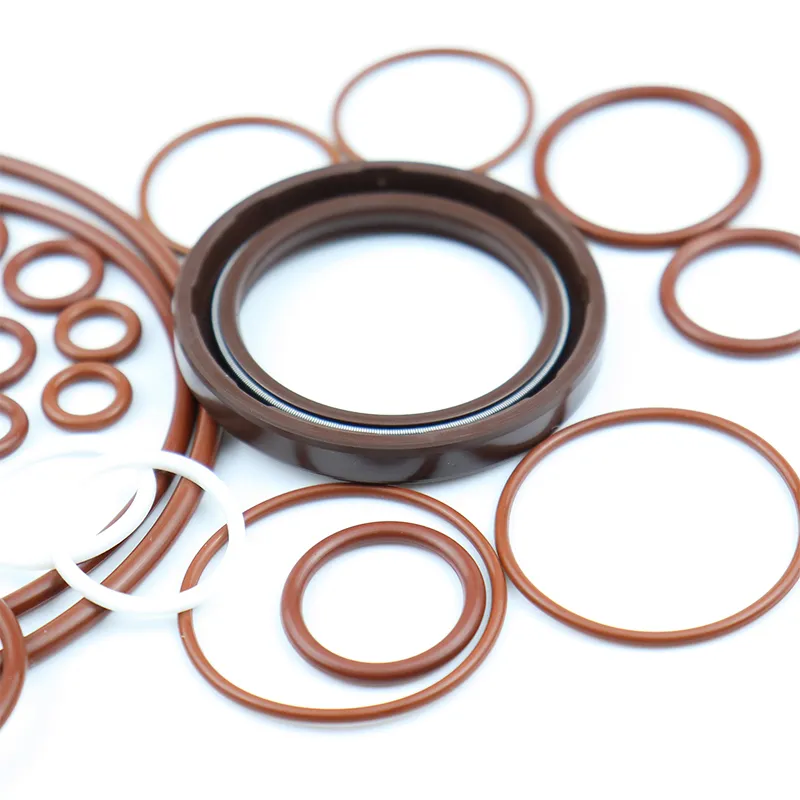

In the world of engineering and machinery, seals play a crucial role in ensuring the proper functioning of various components. Among these seals, the 50x65x8 oil seal stands out as a vital part used in a variety of applications. Understanding its significance requires a closer look at its dimensions, functionality, and the materials used in its construction.

The designation 50x65x8 refers to the specific measurements of the oil seal. These dimensions indicate that the seal has an inner diameter of 50 mm, an outer diameter of 65 mm, and a thickness of 8 mm. The numbers are crucial because they ensure that the seal fits perfectly within designated machinery, preventing any leakage of fluids and maintaining operational integrity. In many mechanical systems, even a slight mismatch can lead to catastrophic failures, making the correct dimensions of utmost importance.

Oil seals, including the 50x65x8 model, primarily serve to prevent the leakage of lubricants while keeping contaminants out of the internal components of machinery. This sealing action is essential in various industries, including automotive, aerospace, and manufacturing. In engines, for instance, the oil seal prevents engine oil from leaking into other compartments, which could result in mechanical failure, excessive wear, and decreased efficiency. The 50x65x8 oil seal ensures that the lubricant stays in place, providing the necessary protection for moving parts against friction and wear.

50x65x8 oil seal

Moreover, the 50x65x8 oil seal's design often includes a lip that creates a barrier against contaminants

. This lip is critical as it enhances the seal's ability to withstand pressure and resist potential damage from external elements. The robustness of a good oil seal is a fundamental attribute, as seals are subjected to various stresses, including temperature fluctuations, pressure differentials, and chemical exposure. Therefore, the materials chosen for the construction of the 50x65x8 oil seal are equally important. Typically, these seals are made from rubber compounds such as Nitrile, Fluoroelastomer, or silicone, each chosen based on the specific needs of the application. Nitrile rubber offers excellent resistance to petroleum-based oils, while fluoropolymers can withstand higher temperatures and provide better chemical resistance.Furthermore, the installation of the 50x65x8 oil seal plays a significant role in its functionality. Proper installation prevents the seal from becoming damaged during setup, which could lead to premature failure. It is important to ensure that the sealing surface is clean and free of debris before installation. Additionally, using proper tools and techniques will amplify the seal's longevity and performance, translating into reduced maintenance costs and enhanced operational efficiency.

The application of the 50x65x8 oil seal spans across numerous fields. In automotive engineering, it is commonly used in components like wheel bearings, gearboxes, and oil pumps. The seal's effectiveness in preventing leaks is essential for the overall performance and reliability of vehicles. In the manufacturing sector, it finds usage in various machinery, ensuring that production lines operate smoothly without the interruption of oil leaks or contamination.

In conclusion, the 50x65x8 oil seal is more than just a simple component; it is a crucial element in safeguarding the functionality of various machinery across multiple industries. Its precise dimensions, robust design, and effective sealing capabilities make it indispensable for preventing lubricant leakage and prolonging the life of mechanical systems. Understanding the role of this oil seal emphasizes the importance of careful selection and installation in maintaining operational excellence. As technology continues to advance, the importance of such seals will only increase, highlighting the ongoing relevance of components like the 50x65x8 oil seal in modern engineering practices.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories