2 月 . 15, 2025 15:32 Back to list

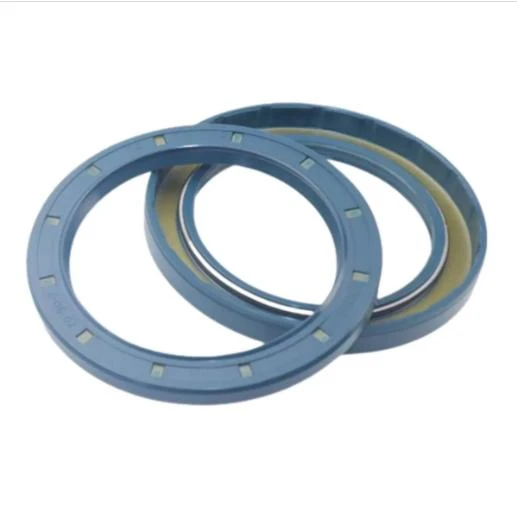

Standard High Pressure TCV Type Hydraulic Oil Seal

The authority of using a 50x65x8 oil seal in machinery management is further reinforced by adherence to precision installation techniques. Proper installation is crucial; improper fitting can compromise the integrity of the seal, leading to premature wear or costly downtimes. Employing precision tools and following manufacturer guidelines guarantees that the oil seal fits within the prescribed tolerances, maintaining the reliability and longevity of both the seal and the machinery it serves. When it comes to trustworthiness, reputable manufacturers play a pivotal role. Investing in oil seals from established and respected suppliers assures compliance with industry standards and even exceeds them. Certifications and adherence to ISO standards reveal a seal's capability to meet the rigorous demands of today's machinery environments, further validating the investment in these essential components. In real-world applications, users often report enhanced operational durability and fewer maintenance interventions when using correctly specified and installed 50x65x8 oil seals. From automotive garages to industrial workshops, the testimonials echo a consistent theme reliable oil seals equate to reduced equipment downtime, increased operational efficiency, and ultimately, a more profitable venture. In conclusion, the 50x65x8 oil seal is a small yet profoundly impactful component that demands attention to detail, expertise in materials science, and precision in installation. It stands as a testament to how seemingly minor parts can fundamentally influence the performance and reliability of complex machinery. Understanding and utilizing these seals not only fortifies machinery against wear and tear but also promotes a culture of precision and excellence across the technical landscape.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories