9 月 . 29, 2024 03:37 Back to list

Similar Specifications for 50x65x8 Oil Seal Replacement Options Available Now

Understanding the 50x65x8% Oil Seal Importance and Applications

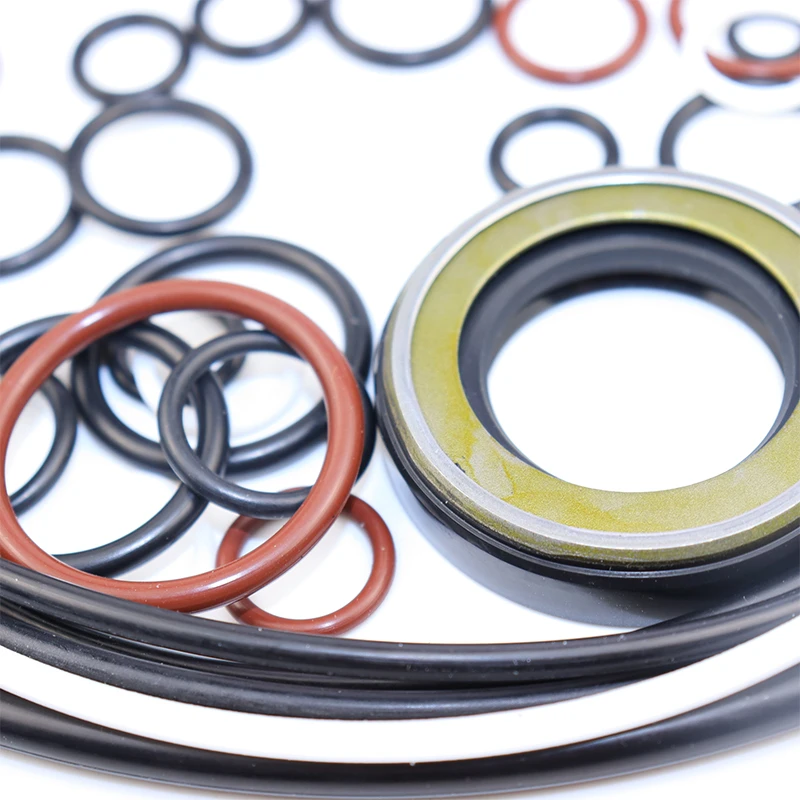

Oil seals are crucial components in various machinery and automotive systems, serving as barriers to prevent the leakage of lubricants and contaminants. Among the different sizes and specifications available, the 50x65x8 oil seal has garnered attention for its wide applicability across several industries. In this article, we will delve into the features, materials, applications, and maintenance of the 50x65x8 oil seal.

Specifications and Features

The designation 50x65x8 indicates the dimensions and thickness of the oil seal, where 50 mm is the inner diameter, 65 mm is the outer diameter, and 8 mm is the thickness. These measurements make the 50x65x8 oil seal suitable for various applications, particularly in hydraulic systems, gearboxes, and automotive engines. The design generally includes a flexible rubber body and a metal casing that adds strength and durability.

One of the standout features of this oil seal is its ability to maintain a reliable sealing function under varying temperatures and pressures. The 8% may refer to a specification regarding its compression rate or the degree of tolerable deformation under load, ensuring a tight fit and preventing oil leakage.

Materials Used

Oil seals are typically manufactured from rubber compounds, with a variety of synthetic materials available to enhance performance. Common materials for the 50x65x8 oil seal include nitrile rubber (NBR), fluorocarbon (FKM), and silicone rubber. NBR is particularly popular due to its excellent resistance to petroleum-based oils and its affordability. In more demanding environments, FKM seals offer superior chemical resistance and high-temperature stability, making them suitable for specialized applications.

Applications

The versatility of the 50x65x8 oil seal allows it to be used across numerous industries, including

50x65x8 oil seal

1. Automotive In vehicles, these oil seals are essential for maintaining engine integrity and ensuring that oil is contained within the engine block, thereby preventing leaks that can lead to performance degradation and increased emissions.

2. Industrial Machinery Many factories use machinery that requires oil lubrication for smooth operation. The 50x65x8 oil seal helps to ensure that these lubricants do not escape, allowing for smoother operation and reduced maintenance costs.

3. Hydraulics In hydraulic systems, oil seals help in maintaining the necessary hydraulic pressure while preventing fluid leaks, which can compromise the system's efficiency.

4. Agricultural Equipment Tractors and other agricultural machines heavily rely on oil seals like the 50x65x8 to ensure that their hydraulic and lubrication systems function correctly, even in harsh operating conditions.

Maintenance and Replacement

Maintaining the integrity of oil seals is vital for the longevity of the machinery they guard. Regular inspections should be conducted to identify any signs of wear, such as cracking or deformation of the seal. If leaks are detected or if the performance of the machinery begins to decline, it may be time to replace the oil seal.

When replacing the 50x65x8 oil seal, it is crucial to ensure that the new seal is compatible with the specific application and operational conditions, including temperature and fluid type. Proper installation techniques should also be employed to avoid damaging the seal during installation.

Conclusion

The 50x65x8 oil seal is a small but significant component that plays an integral role in the efficiency and functionality of various machines and vehicles. Understanding its specifications, materials, and applications can help industries better manage their equipment and minimize the risk of oil leaks and contamination. By performing regular maintenance and timely replacements, operators can extend the life of their machinery and enhance overall operational efficiency. In a world where machines are the backbone of productivity, the importance of reliable components like the 50x65x8 oil seal cannot be overstated.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories