1 月 . 17, 2025 04:12 Back to list

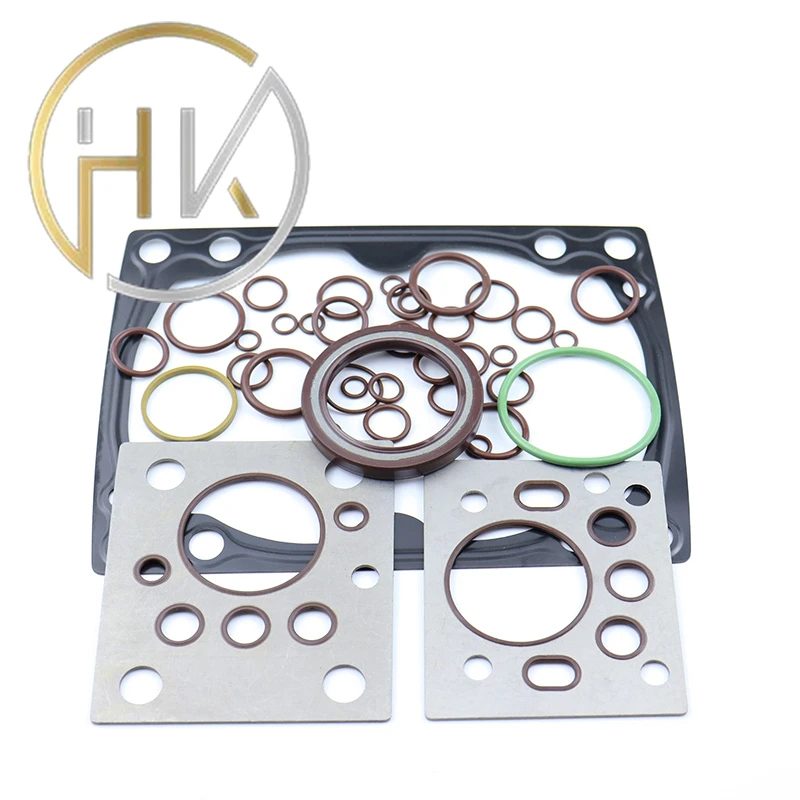

Standard High Pressure TCV Type Hydraulic Oil Seal

Trustworthiness in a product like the 40 80 10 oil seal arises from its proven track record in various demanding applications. Users from sectors like automotive maintenance, industrial manufacturing, and agricultural machinery have reported increased efficiency and reduced maintenance costs after integrating these seals. Testimonials from long-term users highlight the seal’s resilience against wear and tear, even in environments with significant exposure to harsh elements. Furthermore, the installation process of the 40 80 10 oil seal is straightforward, requiring standard tools and minimal technical know-how. This ease of installation not only saves time but also reduces the risk of installation errors, a common concern with complex machinery components. Comprehensive guides and support from manufacturers further bolster the user’s confidence, demonstrating the seal's reliability and ease of use. Emphasizing sustainability, the materials used in the construction of the 40 80 10 oil seal are often recyclable and comply with environmental regulations. This commitment to eco-friendly practices ensures that while the seal performs exceptionally well, it also contributes to reducing the environmental footprint of industrial operations. In summary, the 40 80 10 oil seal distinguishes itself with precise engineering and trusted performance across multiple industries. It embodies the critical balance between durability, compatibility, and ease of installation, making it a staple in maintaining the efficiency and reliability of mechanical systems. For industries seeking a cost-effective and dependable sealing solution, this oil seal offers peace of mind and operational excellence. Overall, its widespread acclaim comes from a blend of real-world effectiveness and robust design, affirming its place as a key component in the realm of industrial and automotive applications.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories