10 月 . 18, 2024 03:05 Back to list

Dimensions and Specifications of 35x72x10mm Oil Seal for Various Applications

Understanding 35x72x10 Oil Seal Properties, Applications, and Importance

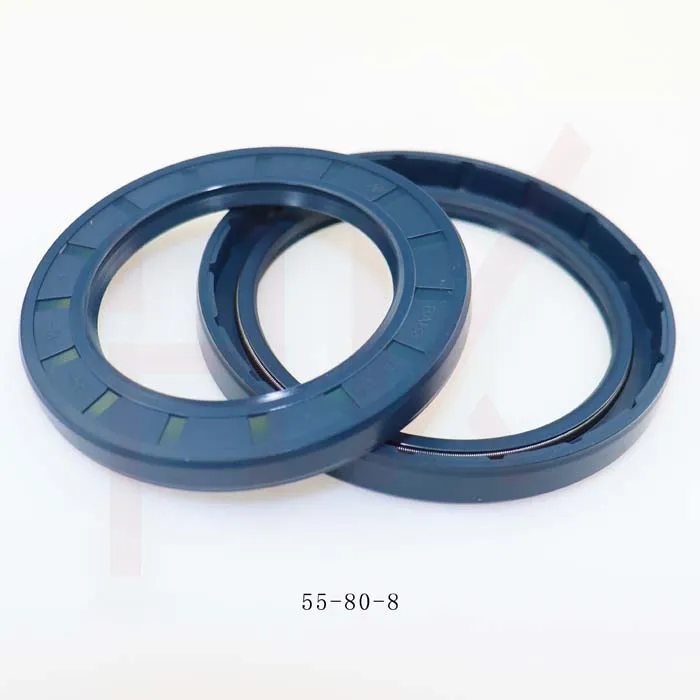

Oil seals, also known as oil seals or lip seals, are critical components used across various industries to prevent the leakage of lubricants and fluids, as well as to keep contaminants out. The designation 35x72x10 provides specific information about the dimensions of a particular oil seal, and understanding these specifications along with the functionality of oil seals is vital for optimal machinery performance.

Key Specifications

The numbers 35x72x10 refer to the dimensions of the oil seal

- 35 mm This is the inner diameter (ID) of the seal, indicating that it fits on a shaft with a diameter of 35 mm. - 72 mm This is the outer diameter (OD) of the seal, which specifies the diameter of the housing or bore into which the seal will be installed. - 10 mm This indicates the thickness of the seal, which affects how well it can maintain a barrier against fluid leakage.

The 20 in the description typically refers to the type of material or design feature, such as a specific compound, or it could even indicate a modification to the standard design, such as reinforced structures for enhanced durability.

Types and Materials

Oil seals are made from various materials, including rubber, silicone, or thermoplastics. The choice of material typically depends on the application requirements, such as temperature range, chemical resistance, and mechanical stress. For example, nitrile rubber is commonly used in environments where hydrocarbons are present, while fluorocarbon rubber may be selected for its resistance to high temperatures and aggressive chemicals.

In the case of the 35x72x10 oil seal, manufacturers often use compounds specifically designed for high performance and durability, ensuring that the seals can withstand the operational conditions they will face. This may include high temperatures, exposure to different types of oils or fluids, and consistent wear from mechanical movement.

35x72x10 oil seal

Applications

Oil seals are ubiquitous in machinery and equipment across multiple sectors. The 35x72x10 oil seal can be found in various applications, including

1. Automotive In vehicles, these seals are commonly utilized in engines, transmissions, and wheel assemblies to prevent oil leaks and ensure efficient performance. 2. Industrial Machinery In manufacturing processes, oil seals maintain the lubrication of bearings and shafts, preventing contamination from dust and moisture. 3. Aerospace Oil seals are crucial in aircraft systems, where reliability and performance are critical to safety. 4. Agricultural Equipment These seals play a vital role in tractors and other equipment by preventing hydraulic fluid leaks and maintaining the health of powertrain components.

Importance of Proper Installation

The effectiveness of an oil seal significantly depends on its proper installation. Incorrect installation can lead to premature failure or leaks, exacerbating wear on machinery and increasing maintenance costs. It is essential to follow manufacturer guidelines during installation, and special attention must be paid to the condition of the shaft and housing to ensure a proper fit.

Benefits of High-Quality Oil Seals

Investing in high-quality oil seals, such as the 35x72x10 variety, brings numerous benefits. They help in maintaining the operational efficiency of machinery, reduce the risk of contamination, and prolong the life of critical components. Additionally, well-functioning oil seals contribute to environmental protection by minimizing leakages that can pollute local ecosystems.

Conclusion

In summary, the 35x72x10 oil seal is a small yet essential component that plays a significant role in ensuring the smooth functioning of various machinery and vehicles. Understanding its specifications, applications, and installation requirements is crucial for engineers, maintenance personnel, and operators alike. By choosing the right oil seal and ensuring its proper installation, businesses can enhance equipment longevity, reduce operational costs, and maintain environmental standards, making it a critical consideration in any industry where fluid containment is necessary.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories