2 月 . 16, 2025 04:24 Back to list

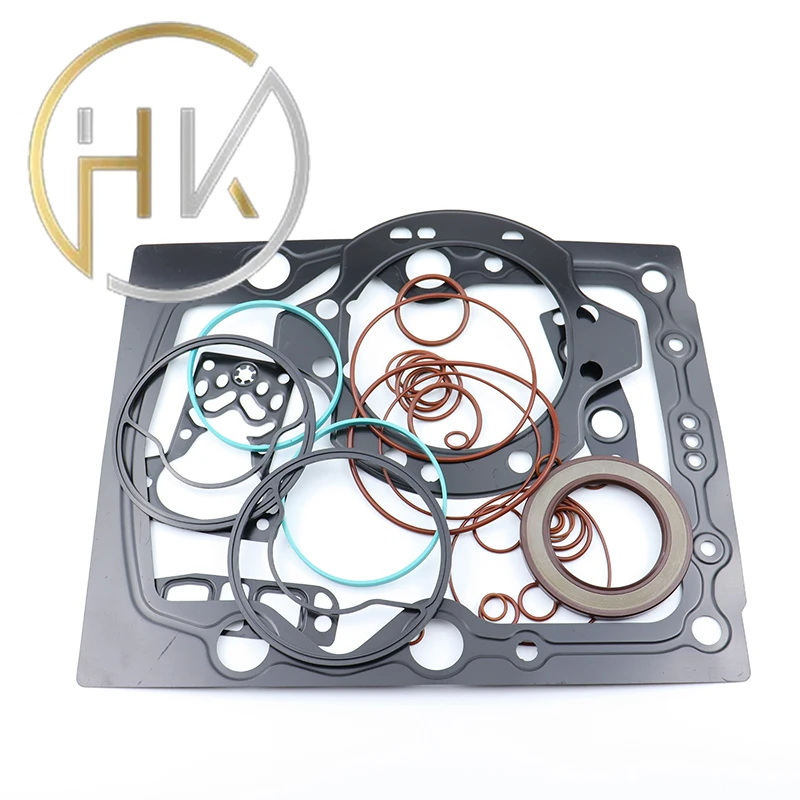

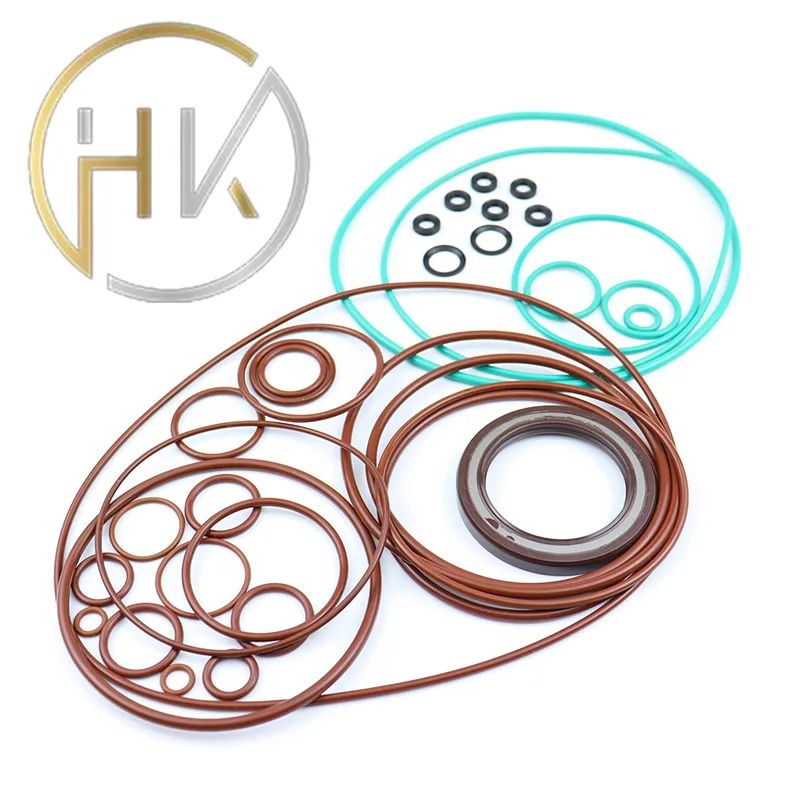

35x50x8 oil seal

An amalgamation of experience and technical knowledge is indispensable for selecting the right oil seal. Each application demands a unique evaluation of the operating environment and conditions load capacities, temperature variations, and exposure to chemicals. Consulting with manufacturers and suppliers provides access to indispensable knowledge and customized solutions, ensuring that the chosen oil seal meets the operational requirements accurately. The authority of the oil seal is not only a result of its individual performance but also its contribution to the broader system. In automotive applications, for example, reliable oil seals enhance engine efficiency by maintaining precise lubrication, which optimizes performance and reduces friction and wear. In industrial settings, effective oil sealing reduces maintenance downtime, saving costs and boosting productivity, making them integral to operations. Trustworthiness in the 35x50x8 oil seal is reinforced by documented field expertise and testing, rigorously ensuring that they meet or exceed ISO standards. Manufacturers consistently invest in research and development to innovate and adapt to evolving industrial needs, further cementing this trust. Operators can rely on these oil seals, assured by the rigorous quality control that goes into their production and testing. Ultimately, the 35x50x8 oil seal embodies excellence by fusing empirical experience and engineering prowess. While it may not demand daily commendations or widespread recognition, its quiet efficiency and reliability earn it a critical place in mechanical operations. Understanding its specifications, installation, and function garners respect and appreciation for its role in prolonging the machinery’s lifespan, securing both performance and safety. Through their inconspicuous yet indispensable performance, oil seals like the 35x50x8 establish their unwavering significance across various industries.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories