11 月 . 01, 2024 14:31 Back to list

Similar Oil Seal Specifications and Applications Overview for Industrial Use

The Importance of the 35% 2072 2010 Oil Seal in Industrial Applications

In the realm of mechanical engineering and maintenance, components often make or break the efficiency of machinery. One such crucial component is the oil seal, specifically the 35% 2072 2010 oil seal. Understanding its significance can offer insights into the optimal performance and longevity of various machines and equipment, particularly in industrial applications.

What is an Oil Seal?

An oil seal, often referred to as a lip seal, is designed to retain oil or lubricants within an assembly, preventing leakage and contamination from external elements. It is commonly employed in rotating shafts, ensuring that the lubricating oil remains contained while keeping dirt and other foreign particles out. A well-functioning oil seal contributes significantly to the overall reliability and efficiency of a machine.

The Specifics of 35% 2072 2010 Oil Seal

The designation 35% 2072 2010 refers to specific dimensions and material characteristics that are integral to the function of this oil seal. The first two digits, 35, typically indicate the inner diameter of the seal in millimeters, while the following series (2072 and 2010) may describe its outer diameter and thickness, respectively. These precise specifications ensure that the oil seal fits perfectly within its designated housing, minimizing the risk of failure due to misfitting.

Material Composition

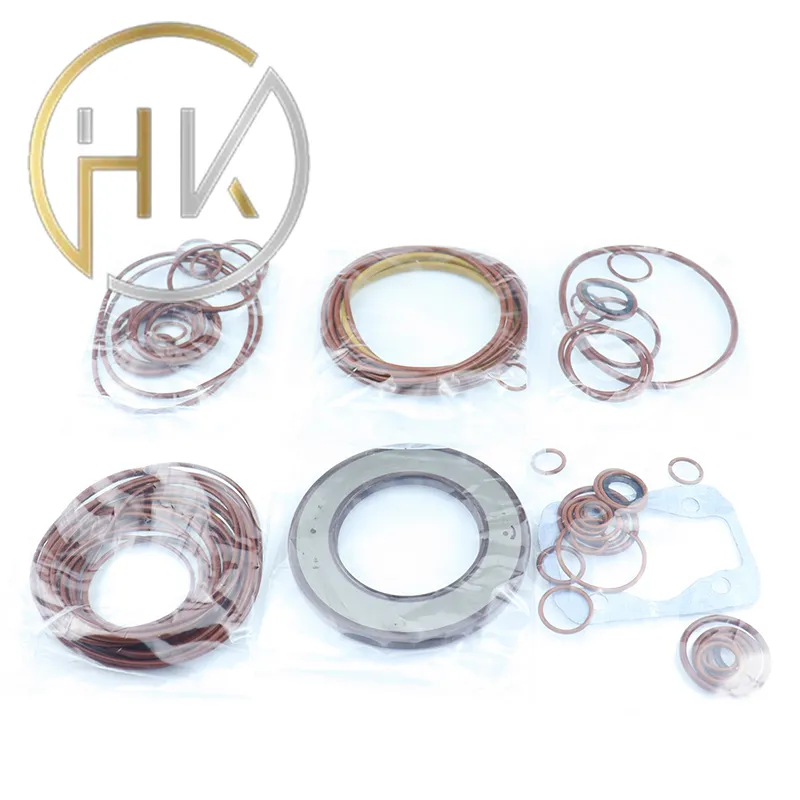

35 72 10 oil seal

Oil seals can be made from a variety of materials including rubber, plastic, and composite materials. The 35% 2072 2010 oil seal is likely to be fabricated from high-quality elastomers that can withstand fluctuations in temperature and pressure. The material's resiliency is vital for preventing wear and tear, which can lead to leaks. Moreover, the right material selection enhances the oil seal's resistance to chemicals and abrasives, which is particularly important in industrial settings where machinery is often exposed to harsh conditions.

Applications in Industry

The use of the 35% 2072 2010 oil seal is prevalent across numerous industries, including automotive, aerospace, manufacturing, and marine applications. In automotive engines, it plays an essential role in preventing oil from leaking out, which not only assures efficiency but also minimizes the risk of engine damage. In industrial machinery, these seals safeguard the internal lubrication of gears and bearings, ensuring smooth operation and prolonging the life of critical components.

Benefits of Using Quality Oil Seals

Employing high-quality oil seals like the 35% 2072 2010 can result in significant long-term savings for businesses. Reducing leakage helps maintain optimal lubrication, which in turn minimizes wear and tear on machinery, decreases maintenance costs, and enhances operational efficiency. Furthermore, a reliable oil seal can prevent environmental contamination caused by leaking lubricants, adhering to environmental standards and regulations.

Conclusion

In conclusion, the 35% 2072 2010 oil seal exemplifies the crucial role that seemingly small components play in the overall functionality of machinery. Its precise engineering, material composition, and versatility in applications make it an indispensable element in the industrial sector. Investing in quality oil seals not only enhances the performance of machinery but also contributes to sustainability and cost-effectiveness in operations. The awareness of such components leads to informed decisions in maintenance and engineering practices, ensuring machinery runs smoothly and efficiently for years to come.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories