1 月 . 15, 2025 09:58 Back to list

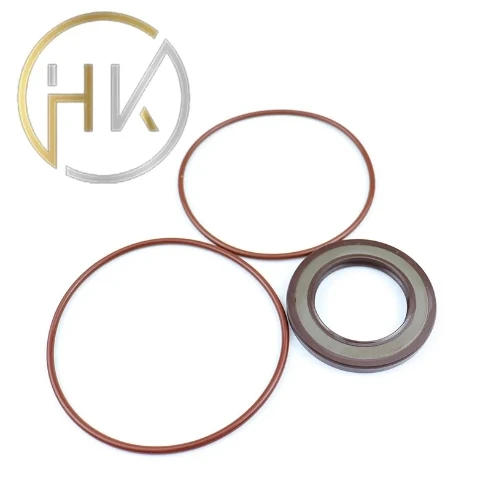

Standard Hydraulic DKB Type Dustproof Wiper Oil Seal

But beyond technical specifications, the trustworthiness of the 30x52x7 seal is documented by countless real-world applications and industry testimonials. Users consistently report extended lifecycle benefits, with vast reductions in the frequency of maintenance interventions. Its wide acceptance across varied sectors demonstrates a seal that has been tested rigorously under real operational conditions, consistently outperforming many alternatives. Turning to application versatility, the 30x52x7 seal is not limited by sector-specific constraints. It finds applications in hydraulic systems, motor vehicles, and industrial machinery, among other uses. Its adaptability to different lubricant types and temperatures underpins its universal appeal. Such versatility underscores its role as a pivotal element in mechanical solutions seeking to uphold high operational standards while reducing costs associated with seal failures and replacements. Moreover, adopting the 30x52x7 seal reflects a commitment to sustainability. By significantly reducing the need for frequent replacements and ensuring efficient operations, this seal contributes to lower resource consumption and minimized waste, aligning with broader environmental objectives crucial in contemporary industrial practices. In conclusion, the 30x52x7 seal presents itself as a product steeped in engineering excellence. By merging innovative design with advanced material technology, it offers reliability and performance that stand the test of time. Industry professionals trust this seal, not only for its proven track record but also for the confidence it instills in operational continuity. Its expert design ensures that each seal functions optimally, thus fostering trust and authoritativeness in every application it serves. This reliability makes the 30x52x7 seal a cornerstone of mechanical integrity across various industries, providing an unparalleled solution to sealing challenges. As industries evolve, the adaptability and superior performance of the 30x52x7 seal ensure that it remains a staple choice for engineers and decision-makers dedicated to maintaining the highest standards of excellence in their operations.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories