1 月 . 25, 2025 00:33 Back to list

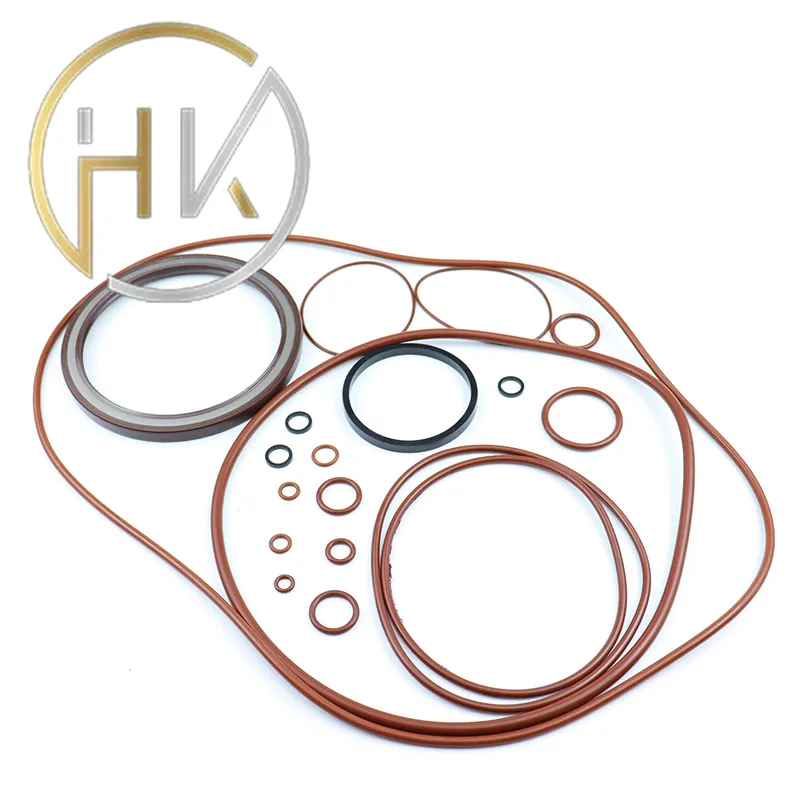

2 inch hydraulic cylinder seal

Adhering to operational best practices enhances trustworthiness and authority in using these components. Users should be cautious about overloading the system and operating beyond specified pressure limits, as these actions can lead to seal deformation or failure. Maintaining a detailed log of maintenance schedules and any anomalies observed during inspections builds a foundation of reliability and transparency. For professionals seeking authoritative insights into hydraulic systems, it's prudent to rely on manufacturers and suppliers with proven expertise and a track record of quality. Reputable suppliers usually accompany their products with comprehensive technical documentation, installation guides, and support, which are invaluable resources for technicians and engineers alike. In particular, when dealing with specialized components like 2-inch hydraulic cylinder seals, engaging with industry experts ensures you receive dependable products tailored to your exact requirements. Innovations in seal technology, driven by ongoing research and development, contribute to enhanced performance characteristics, such as improved thermal stability and wear resistance. Staying abreast of these technological advancements through professional forums, workshops, and collaboration with knowledgeable suppliers is integral to maintaining an edge in hydraulic system management. Ultimately, the successful application of a 2-inch hydraulic cylinder seal lies in understanding its role within the system, selecting the right product for the specific conditions, and following meticulous installation and maintenance protocols. By prioritizing these aspects, organizations can uphold machinery efficiency, reduce downtime, and achieve sustainable operational excellence.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories