9 月 . 28, 2024 17:01 Back to list

25x38x7 mm oil seal specifications and applications for enhanced machinery performance

Understanding the Significance of 25x38x7 mm Oil Seals

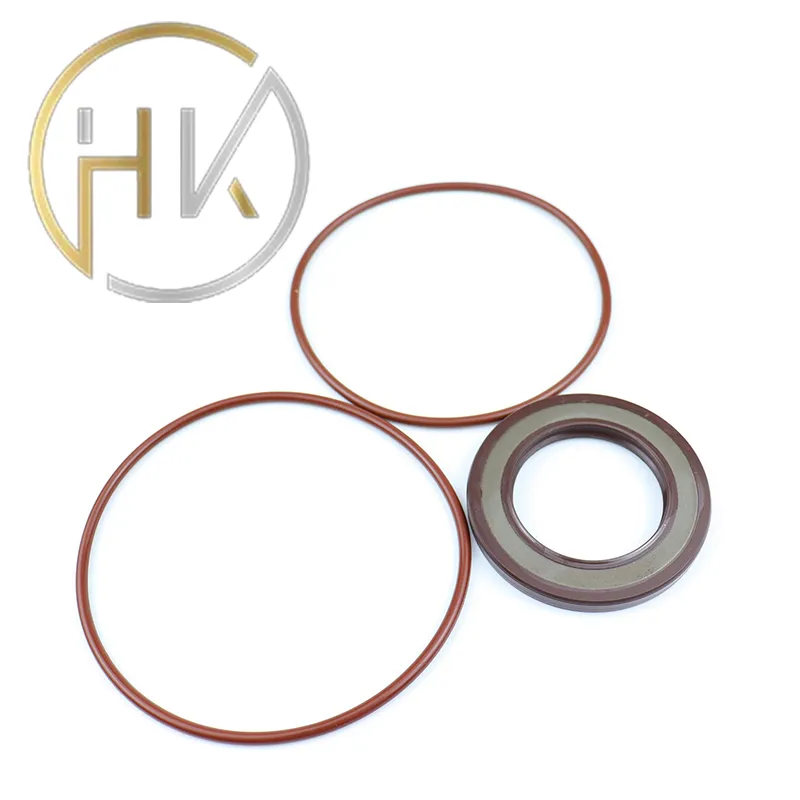

Oil seals are crucial components in various machinery and equipment, playing a vital role in maintaining optimal performance and longevity. Among the different types of oil seals available, the 25x38x7 mm oil seal stands out due to its unique dimensions and applications. This article will delve into the characteristics, applications, advantages, and maintenance of these essential components.

What is an Oil Seal?

An oil seal, also known as a radial seal or rotary seal, is a mechanical device used to seal the interface between stationary and rotating parts. Its primary purpose is to prevent the leakage of lubricating oil and to keep contaminants such as dirt and dust from entering the machinery. Oil seals are composed of several materials, including rubber, polyurethane, and metal, enabling them to withstand various operating conditions and environments.

Dimensions and Specifications

The designation '25x38x7 mm' refers to the oil seal's dimensions - 25 mm The inner diameter (ID), which fits snugly around the shaft. - 38 mm The outer diameter (OD), which fits into the housing or bore. - 7 mm The width of the seal, which indicates how thick the sealing element is.

These specifications make the 25x38x7 mm oil seal suitable for a range of applications, particularly in automotive and industrial machinery where protection against oil leakage and external contaminants is essential.

Applications of 25x38x7 mm Oil Seals

The 25x38x7 mm oil seal finds a diverse range of applications across multiple industries

. Some of the most common uses include1. Automotive Applications Oil seals are used in engines, transmissions, and differentials to contain engine oil and transmission fluid while preventing external contaminants from entering these critical components.

2. Industrial Machinery These oil seals are integral to various industrial machines, including pumps, gearboxes, and hydraulic cylinders, where they help maintain lubrication and reduce wear on moving parts.

3. Agricultural Equipment Tractors and other farming machinery utilize oil seals to protect against harsh working conditions and ensure smooth operation.

4. Marine Applications In boats and ships, oil seals serve to safeguard engines and other critical systems from both oil leaks and seawater intrusion.

25x38x7 oil seal

Advantages of 25x38x7 mm Oil Seals

1. Leak Prevention The primary benefit of oil seals is their ability to prevent oil leakage, which is critical for maintaining operational efficiency and preventing environmental contamination.

2. Dirt and Contamination Resistance These seals effectively block contaminants, ensuring that the lubricating oil remains clean and extends the life of the machinery.

3. Versatility The 25x38x7 mm size makes these oil seals suitable for various applications, from small engines to larger industrial machines.

4. Cost-Effectiveness Regular usage of oil seals can lead to lower maintenance costs over time by preventing leaks and machine failures.

Maintenance and Care

Although oil seals are designed for durability, proper maintenance is essential to maximize their lifespan. Here are some tips

1. Regular Inspection Routinely check the oil seal for signs of wear, damage, or leakage. Early detection can prevent further issues.

2. Proper Installation Ensure that the oil seal is correctly installed according to manufacturer specifications to avoid premature failure.

3. Lubrication Ensure that the sealing surface is properly lubricated during installation to reduce friction and wear.

4. Environment Consideration Be mindful of the operating environment. Extreme temperatures and exposure to harsh chemicals can affect the seal’s performance and longevity.

Conclusion

The 25x38x7 mm oil seal is a small yet indispensable component that plays a significant role in the functionality of various machines across multiple industries. Understanding its characteristics, applications, and maintenance requirements can help operators and technicians ensure that their equipment runs smoothly and efficiently. Regular inspections and proper care of oil seals can lead to longer service life and reduced operational costs, making them a vital investment in machinery maintenance.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories