2 月 . 15, 2025 18:04 Back to list

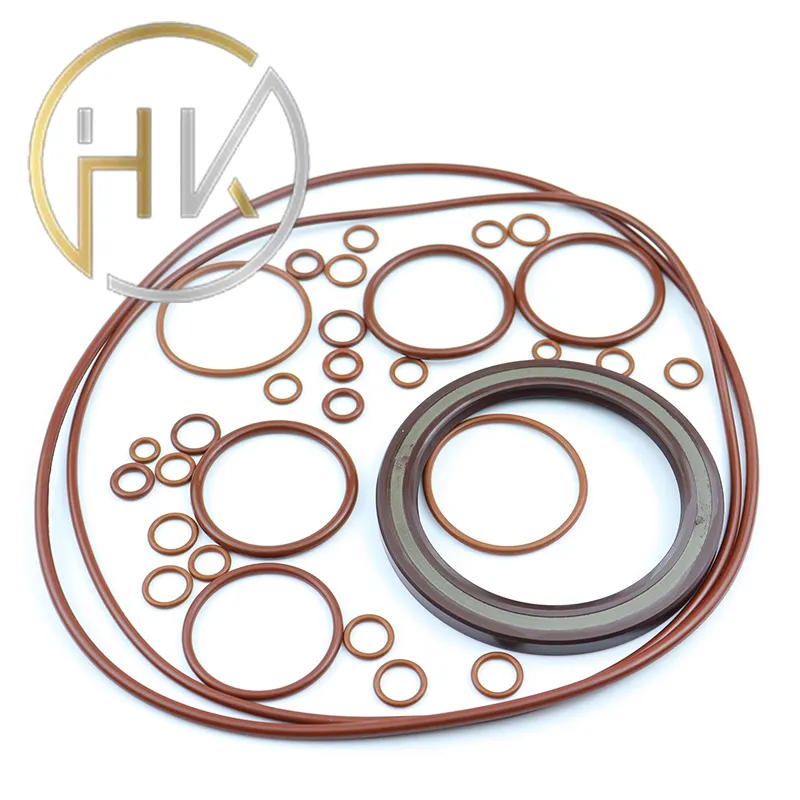

Standard High Pressure TCV Type Hydraulic Oil Seal

Furthermore, the design of the 25x35x7 oil seal incorporates sophisticated lip dynamics. The sealing lip of these oil seals is precision-crafted to maintain uniform contact with the shaft, effectively barring foreign particles and retaining the lubricant. This design is complemented by a spring-loaded mechanism that ensures consistent pressure, accommodating shaft misalignment and vibrations without compromising sealing capabilities. Authoritativeness Credibility Backed by Standards Manufacturers and industry associations back the quality of the 25x35x7 oil seal through stringent compliance with international standards such as ISO 9001. These certifications affirm the product’s quality, adherence to industry regulations, and commitment to performance excellence. Companies that utilize seals meeting these standards benefit from reduced risk of equipment failure and enhanced operational safety, which is crucial in high-stakes industries like aerospace and automotive engineering. Trustworthiness Building Confidence Through Proven Performance The trust placed in the 25x35x7 oil seal is built on a foundation of consistent performance and proven results. With a history of minimizing mechanical failures and enhancing operational efficiency, these seals have become a staple among professionals seeking reliability in their machinery. Collaboration with reputed suppliers ensures authenticity and quality control, further bolstering user confidence. Ultimately, the 25x35x7 oil seal is more than just a mechanical component; it is a strategic element in engineering design. Its integration into machinery underscores a commitment to precision, endurance, and operational excellence. By prioritizing these factors, companies can achieve significant cost savings, operational efficiencies, and extend the usability of their equipment, making the 25x35x7 oil seal an indispensable choice in advanced mechanical applications.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories