1 月 . 15, 2025 09:53 Back to list

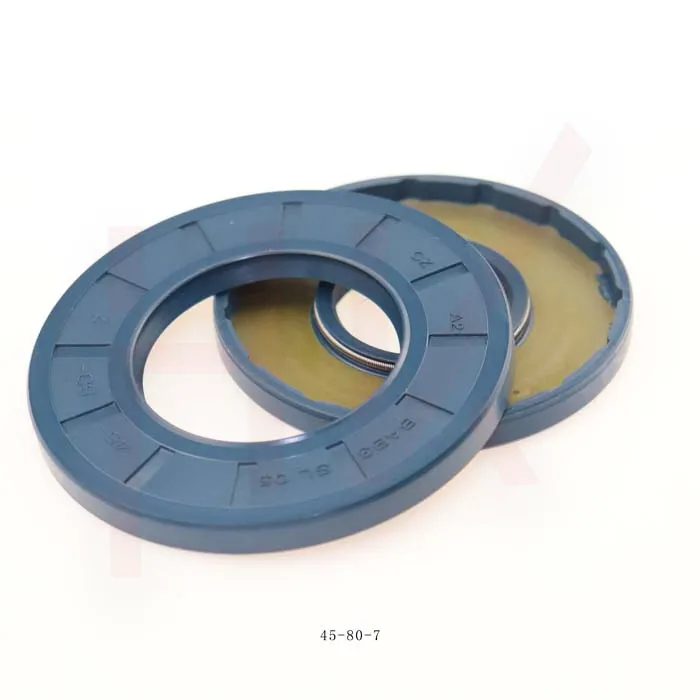

25x35x7 oil seal

The authoritativeness of information regarding oil seals is supported by comprehensive studies and industry standards that detail their usage. Industry organizations provide specifications that trusted manufacturers adhere to when designing these components. Relying on such established guidelines ensures that what is in use today represents the culmination of years of testing and refinement, ultimately providing confidence in the product. From a trustworthiness perspective, investing in 25x35x7 oil seals from reputable suppliers guarantees a product that meets industry standards and performs reliably under the stated conditions. Suppliers that maintain transparency regarding the materials used and the testing performed provide an additional layer of assurance that the oil seal will function as expected. In conclusion, incorporating high-quality 25x35x7 oil seals can significantly enhance the operational reliability of various mechanisms. With their ability to prevent leaks and guard against contamination, they not only ensure the efficient functioning of components but also extend the life of the machinery. In an industrial setting where every minute of operation counts, choosing the right seal size and material isn’t just beneficial; it’s essential. As industries continue to evolve, the choice of components, such as oil seals, serves as a testament to the ongoing commitment to performance and durability.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories