10 月 . 13, 2024 01:23 Back to list

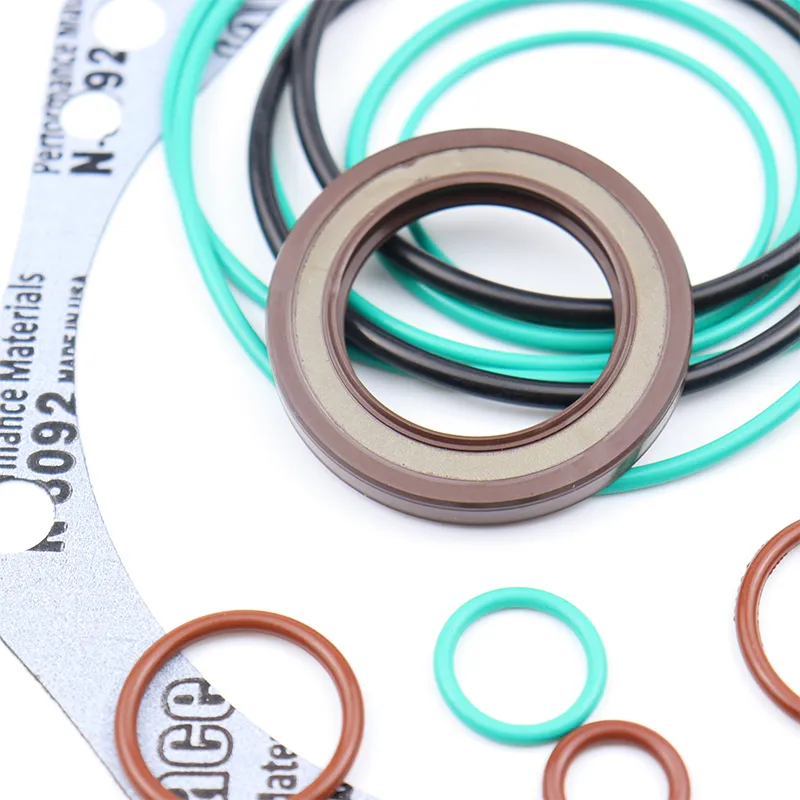

25 47 7 oil seal

The Importance of 25% Oil Seal A Comprehensive Overview

In the world of mechanical engineering and industrial applications, the significance of components like oil seals cannot be overstated. Among these, the 25% oil seal stands out due to its unique attributes and critical role in the functionality and longevity of various machines and systems. This article delves into what a 25% oil seal is, its applications, advantages, and the best practices for maintenance and replacement.

What is an Oil Seal?

An oil seal, also known as a fluid seal, is a type of mechanical seal that plays a fundamental role in preventing the leakage of lubricants and fluids from a system. It is commonly made from materials such as rubber, silicone, or polyurethane, ensuring robust performance. The term 25% oil seal refers to the specific formulation or design that is optimal for certain applications, particularly those that require moderate resistance to oil and other fluids.

Applications of 25% Oil Seal

The 25% oil seal is utilized across various industries, including automotive, aerospace, manufacturing, and oil & gas. In automotive applications, for example, it is crucial for sealing engine components, gearboxes, and transmission systems, where the presence of oil is constant. It ensures a tight seal, preventing oil from leaking out or contaminants from getting in, which is paramount for the efficient operation of these systems.

In the aerospace industry, oil seals are critical for maintaining the integrity of hydraulic systems and engines. Similarly, in manufacturing equipment, these seals protect against fluid leakage in hydraulic pumps and motors, thereby improving efficiency and reliability.

Advantages of the 25% Oil Seal

1. Efficiency The primary function of an oil seal is to prevent leakage. The 25% oil seal provides an excellent balance between flexibility and durability, leading to enhanced operational efficiency.

2. Durability Made from high-quality materials, this type of oil seal is resistant to wear and degradation. It can withstand a variety of environmental conditions, including fluctuations in temperature and exposure to different chemicals.

25 47 7 oil seal

3. Cost-Effective The maintenance of machinery can be costly, especially when it involves fluid leaks or component replacements. Using a durable oil seal minimizes these risks, providing long-term savings.

4. Performance Reliability In systems where oil leakage can lead to severe performance issues or even catastrophic failures, a reliable oil seal becomes essential. The 25% oil seal provides reliability that engineers can trust.

Best Practices for Maintenance and Replacement

To ensure the longevity and effectiveness of a 25% oil seal, appropriate maintenance practices should be followed

1. Regular Inspections Routine checks for signs of wear, such as cracks, deformation, or leakage, are crucial. Identifying issues early on can save significant repair costs.

2. Proper Installation Correct installation is paramount for the optimal performance of an oil seal. Following manufacturer specifications and guidelines during installation can help avoid premature failure.

3. Compatibility Checks Always check that the oil seal is compatible with the fluids and operating conditions of the application. Using the wrong seal can lead to failure.

4. Timely Replacement Oil seals, like all mechanical components, have a lifespan. It is essential to replace them at intervals recommended by the manufacturer or sooner if deterioration is observed.

Conclusion

The 25% oil seal serves as an indispensable component in various industries, ensuring the efficient operation of machinery by preventing fluid leaks. Its durability, efficiency, and cost-effectiveness make it a preferred choice among engineers and maintenance professionals. By adhering to best practices in maintenance and timely replacement, businesses can maximize the life of their equipment and maintain peak operational performance. As technology evolves, the importance of such components will only continue to grow, underscoring the need for ongoing innovation in seal manufacturing and application practices.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories