10 月 . 19, 2024 10:08 Back to list

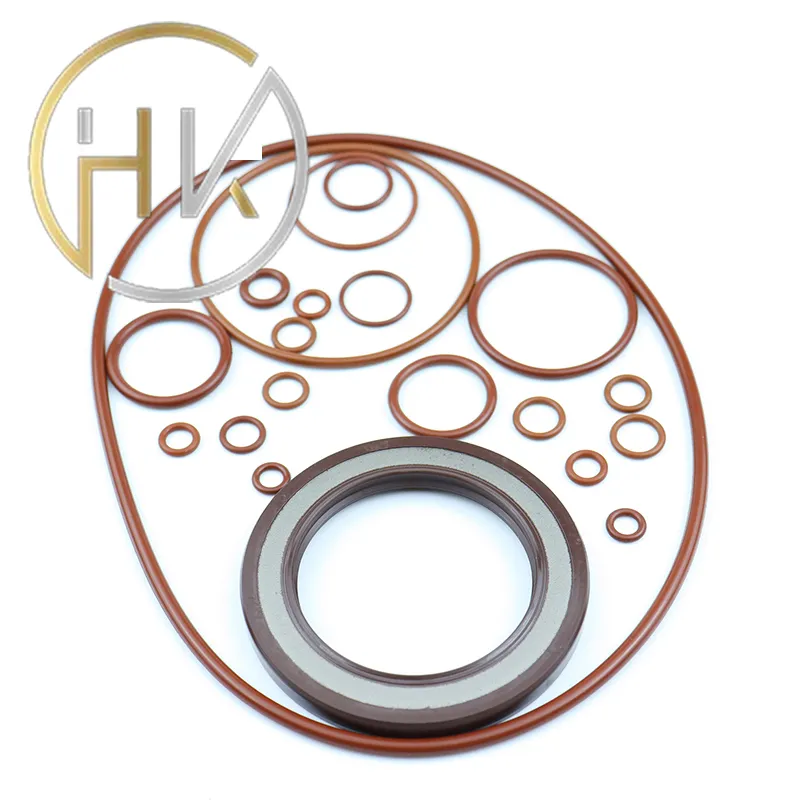

25 35 7 oil seal

The Significance of Oil Seals Focusing on the 25% 2035 7 Oil Seal

In the world of mechanical engineering and manufacturing, oil seals play a crucial role in ensuring the integrity and efficiency of various machinery and automotive applications. One such oil seal that has gained attention is the 25% 2035 7 oil seal, each number representing specific dimensions, material compositions, and performance characteristics. In this article, we will explore the importance of oil seals in machinery, delve into the specific features and advantages of the 25% 2035 7 oil seal, and examine its applications in different industries.

Understanding Oil Seals

Oil seals, also known as radial shaft seals or oil wipers, are designed to seal the gap between stationary and moving components. Their primary function is to prevent the leakage of lubricants, such as oil or grease, from bearings or engine compartments while keeping contaminants such as dirt and dust from entering the machinery. Proper sealing is vital for maintaining the performance and longevity of mechanical systems, reducing wear and tear, and ultimately saving costs on repairs and replacements.

The Importance of Seal Specifications

The designation “25% 2035 7” speaks to specific metrics that define the oil seal's capabilities. The first number, 25%, may indicate the composition of a special elastomer or a specific feature of the seal's design that improves its resilience against various environmental factors. The numbers 2035 and 7 likely refer to the oil seal's dimensions, such as inner and outer diameter and width, which are crucial for ensuring a tight fit and optimal functionality.

The choice of materials in oil seal manufacturing is equally significant. Typically, oil seals are made from rubber materials, thermoplastics, or composite materials specifically engineered to withstand heat, pressure, and chemical exposure. In the case of the 25% 2035 7 oil seal, its material likely offers enhanced durability and resistance to harsh chemicals, ensuring that the seal performs efficiently in demanding environments.

Advantages of the 25% 2035 7 Oil Seal

1. Enhanced Durability Designed to withstand wear and tear over prolonged use, the 25% 2035 7 oil seal can endure cyclical stresses, making it ideal for high-performance machinery.

2. Resistance to Contaminants Its design helps protect against the intrusion of dust, dirt, and moisture, thus prolonging the life of the sealing surface and the overall machinery.

25 35 7 oil seal

3. Robust Performance in Varied Conditions Whether exposed to extreme temperatures, hydraulic fluids, or other challenging conditions, the 25% 2035 7 oil seal exhibits excellent stability and effective sealing performance.

4. Reduced Maintenance Needs By preventing leaks and ensuring smooth operation, this oil seal minimizes the need for frequent maintenance checks and fluid replenishments, leading to enhanced productivity for businesses.

Applications

The 25% 2035 7 oil seal finds a diverse range of applications across various industries

- Automotive In vehicles, oil seals are commonly used in engines, transmissions, and differential assemblies, where fluid retention is crucial for optimal operation.

- Industrial Machinery Manufacturing equipment often relies on oil seals to maintain lubrication in critical components such as pumps, motors, and gearboxes.

- Aerospace Specialized oil seals are essential in aerospace applications, where precision and reliability under extreme conditions are paramount.

- Construction Equipment Heavy machinery used in construction faces severe operational conditions, making robust oil seals like the 25% 2035 7 indispensable for performance reliability.

Conclusion

In summary, the 25% 2035 7 oil seal exemplifies the engineering advancements in sealing technology. Its specific design and material properties make it a standout choice for various applications across multiple industries. By preventing leaks and protecting machinery from contaminants, oil seals such as the 25% 2035 7 contribute significantly to the longevity and efficiency of mechanical systems. As industries continue to evolve and require more durable and reliable components, the importance of effective oil seals in maintaining operational integrity cannot be overstated.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories