9 月 . 25, 2024 01:06 Back to list

25 35 7 oil seal

Understanding the 25% 2035 7 Oil Seal An Integral Component in Mechanical Engineering

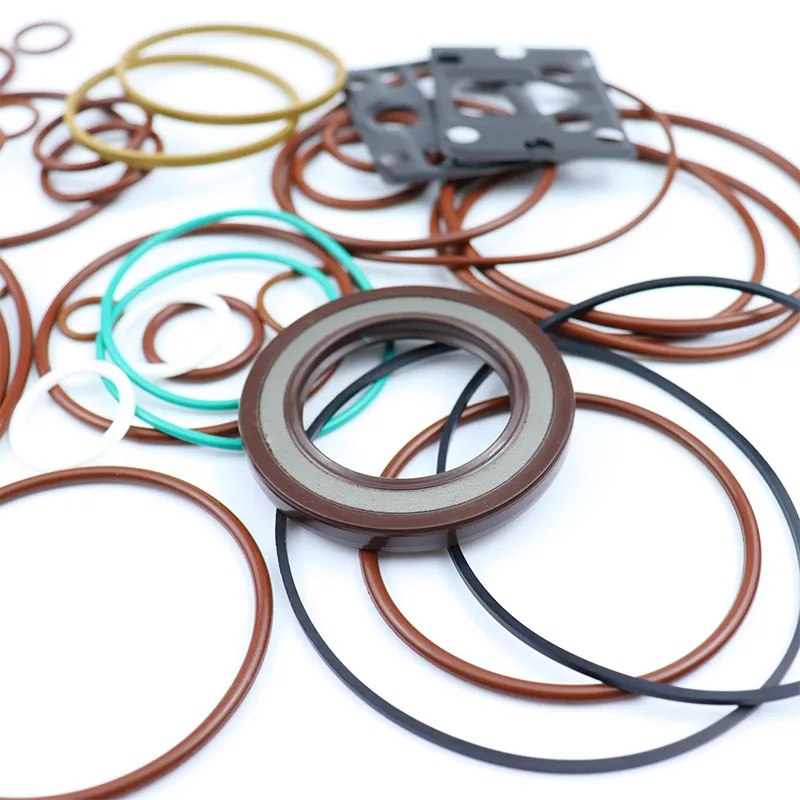

In the realm of mechanical engineering, seals play a crucial role in the successful functioning of machines and their components. Among various types of seals, the oil seal stands out as an essential component in numerous applications. The 25% 2035 7 oil seal, in particular, has gained attention due to its specific characteristics and applications. In this article, we will delve into the significance, functionality, and various facets associated with the 25% 2035 7 oil seal.

What is an Oil Seal?

An oil seal, also known as a radial seal, is designed to retain lubricants and exclude contaminants from entering the system. It is primarily used in rotating shafts, assembling various mechanical engineering applications. The effectiveness of an oil seal is determined by its design, material, and operating conditions.

Breakdown of the 25% 2035 7 Oil Seal

The designation '25% 2035 7' refers to specific dimensions and performance metrics of the oil seal. Each part of the designation serves as a critical identifier providing important details about the seal's size, fit, and functionality

1. 25% This percentage indicates the sealing material's compressibility and oil resistance. A higher percentage typically means better adaptability to different sealing scenarios, accommodating variations in temperature and pressure.

2. 2035 These numbers often represent the dimensional specifics of the oil seal, such as the inner and outer diameters. Accurate dimensions are vital for ensuring a proper fit, which prevents leaks and maintains the integrity of the machinery.

3. 7 This figure could denote the thickness of the oil seal or a specific series identification within a product line, indicating its suitability for specific applications. The thickness of the seal plays a significant role in its durability and capacity to handle pressure variations.

Applications of the 25% 2035 7 Oil Seal

The versatility of the 25% 2035 7 oil seal makes it suitable for various applications across multiple industries

. Here are a few examples25 35 7 oil seal

1. Automotive industry Oil seals are fundamental in vehicles, where they help contain engine oils and transmission fluids while preventing contaminants from entering critical spaces. The 25% 2035 7 oil seal can be found in engines, gearboxes, and differentials.

2. Agricultural machinery Agricultural equipment often operates in harsh conditions, where exposure to dirt, dust, and moisture is common. The 25% 2035 7 oil seal provides effective sealing solutions for machinery like tractors and combine harvesters.

3. Industrial machinery In manufacturing settings, machinery often requires reliable sealing solutions to minimize downtime caused by leaks. The oil seal plays a vital role in hydraulic systems and rotating equipment, ensuring efficient operation.

Advantages of the 25% 2035 7 Oil Seal

The design and characteristics of the 25% 2035 7 oil seal present several advantages

- Durability Manufactured from high-quality materials, these seals can withstand extreme temperature and pressure conditions, making them ideal for heavy-duty applications.

- Prevent Contamination Effective sealing minimizes the ingress of dirt and moisture, which can significantly reduce wear and tear on machinery.

- Cost-Effectiveness By preventing leaks and identifying potential issues early, the 25% 2035 7 oil seal helps extend the lifespan of machinery, ultimately reducing maintenance costs.

Conclusion

In conclusion, the 25% 2035 7 oil seal represents an essential element in a multitude of mechanical systems. Its specific design specifications cater to a variety of applications, demonstrating its versatility and effectiveness. Understanding the intricacies of specification designations like 25%, 2035, and 7, along with the advantages it offers, can significantly benefit those involved in machinery design, maintenance, and troubleshooting. As machinery becomes increasingly sophisticated, the role of high-quality components such as the 25% 2035 7 oil seal remains paramount, underscoring the importance of meticulous engineering in achieving reliable performance.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories