10 月 . 15, 2024 23:20 Back to list

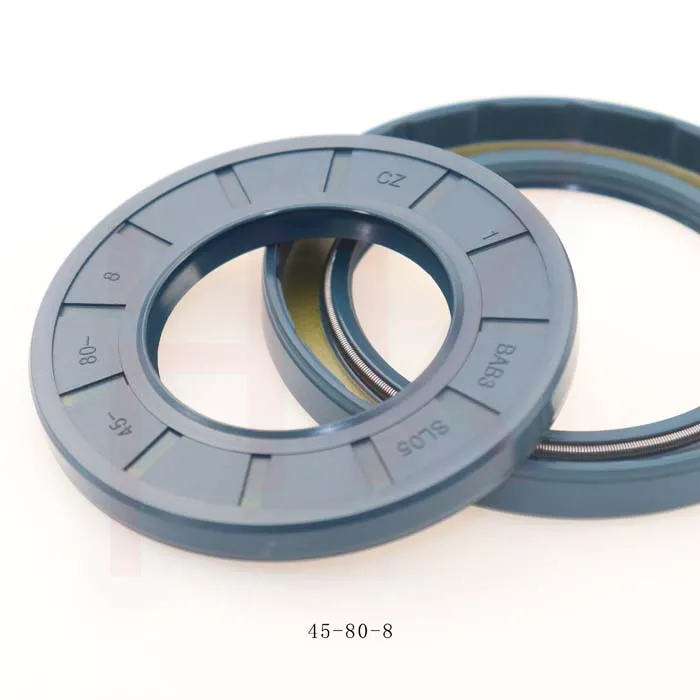

20 35 7 oil seal

Understanding the 20% 35% 7% Oil Seal Applications and Importance

Oil seals are critical components in various mechanical systems, ensuring the integrity and performance of machinery and equipment. Among the various specifications of oil seals, the designation 20% 35% 7% provides essential information regarding their dimensions and suitability for specific applications. This article aims to provide insights into the significance of these specifications and their applications in various industries.

What Does 20% 35% 7% Indicate?

The designation 20% 35% 7% typically refers to the dimensions of the oil seal. In this case, the numbers suggest the following

- 20mm This generally represents the inner diameter of the oil seal. The inner diameter is crucial for fitting the seal snugly onto the shaft or housing. A precise match ensures a proper seal and prevents leakage of lubricants or fluids.

- 35mm This number indicates the outer diameter of the seal. The outer diameter must match the housing cavity where the seal is installed. An improper fit can lead to a failure in sealing capabilities, resulting in contamination or loss of lubricant.

- 7mm This measurement usually refers to the thickness of the oil seal. The thickness plays a vital role in the durability and integrity of the seal, determining its ability to withstand pressure and wear over time.

Importance of Oil Seals in Machinery

Oil seals perform several vital functions in mechanical systems

1. Leak Prevention One of the primary purposes of an oil seal is to prevent the leakage of oils and lubricants from machinery. This is essential in maintaining the required lubricant levels for smooth operation and minimizing wear on components.

2. Contamination Protection Oil seals also protect internal components from contaminants such as dust, dirt, and moisture. By creating a barrier, they extend the lifespan of bearings and other critical parts by ensuring that external particles do not interfere with their operation.

20 35 7 oil seal

3. Pressure Maintenance Many applications require seals to maintain specific pressure levels within a system. Well-fitted oil seals can withstand various pressures, ensuring that systems operate efficiently without risks of failure.

4. Noise Reduction Properly installed oil seals also contribute to reducing operational noise in machinery. They dampen vibrations and support a quieter operation, which is crucial in many industrial applications.

Applications of 20% 35% 7% Oil Seals

The 20% 35% 7% oil seal can be utilized in various applications, including

- Automotive Industry In vehicles, oil seals are used in engines, transmissions, and differentials to prevent oil leaks and protect components from contaminants.

- Industrial Equipment Machinery used in manufacturing and processing often employs oil seals to enhance reliability and reduce maintenance downtime.

- Agricultural Machinery Farmers depend on robust machinery; oil seals help maintain the performance and efficiency of tractors and other agricultural machines.

- Aerospace and Aviation Oil seals in aircraft ensure that lubricants do not leak under extreme conditions, which is vital for the safety and efficiency of flight operations.

Conclusion

The specifications of oil seals, such as 20% 35% 7%, play a crucial role in ensuring the effectiveness of these components across various industries. Understanding these specifications helps in selecting the right seal for specific applications, thereby prolonging the lifespan of machinery and improving operational efficiency. As industries continue to evolve, the importance of reliable oil seals will remain a cornerstone of mechanical functionality.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories