9 月 . 27, 2024 22:07 Back to list

Alternative Sealing Solutions for 20% 35% and 7% Oil Applications

Understanding the 20% 35% 7% Oil Seal A Comprehensive Overview

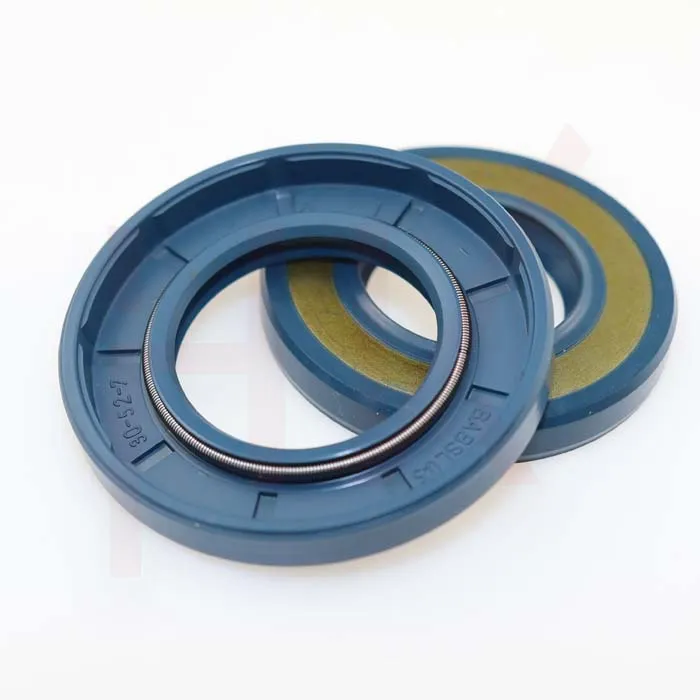

In modern mechanical systems, oil seals, also known as rotary shaft seals or lip seals, play an essential role in ensuring the efficiency and longevity of machinery. Among various types, the 20% 35% 7% oil seal has become prominent due to its specific application in various industries. This article delves into the composition, function, and importance of the 20% 35% 7% oil seal, along with its advantages and applications.

Composition of the 20% 35% 7% Oil Seal

The numerical notation 20% 35% 7% typically refers to the material composition of the oil seal, indicating the proportions of different elements that contribute to its performance characteristics. In the case of the 20% 35% 7% oil seal, it generally comprises

- 20% of a specific polymer or rubber compound This portion often includes elastomers that provide flexibility and elasticity, crucial for forming a tight seal around rotating shafts. - 35% of reinforcing agents These could be fillers like carbon black or silica, enhancing the mechanical strength, wear resistance, and thermal stability of the seal, ensuring it can withstand harsh operating conditions. - 7% of additives Specialty additives can be included to improve the seal’s resistance to chemicals, UV radiation, and extreme temperatures. These enhancements are vital for maintaining the seal's integrity over time.

Functionality of the Oil Seal

The primary purpose of the 20% 35% 7% oil seal is to prevent the leakage of lubricants in hydraulic and automotive systems while keeping contaminants, such as dirt and dust, from entering. It acts as a barrier between moving components, reducing friction and wear – key elements for maintaining the efficiency of machinery. The design of the oil seal, with its lip configuration, allows it to adapt to variations in shaft position and maintains a consistent sealing force against the surface.

Importance in Various Industries

20 35 7 oil seal

The 20% 35% 7% oil seal finds extensive usage across numerous industries, including automotive, manufacturing, and hydraulics. Its importance can be appreciated in several aspects

1. Cost Efficiency By preventing fluid leaks, oil seals help to reduce maintenance costs and downtime in machinery, optimizing productivity. 2. Enhancing Performance In motors and engines, effective sealing ensures proper lubrication, which enhances performance and energy efficiency.

3. Environmental Benefits By containing lubricants and fluids, the seals help in minimizing the risk of spills and environmental contamination, adhering to regulatory standards.

4. Longevity of Machinery A dependable oil seal contributes to the overall lifespan of equipment by preventing internal damage caused by contaminants or lubricant loss.

Challenges and Considerations

While the 20% 35% 7% oil seal is highly effective, there are challenges to consider. Ensure compatibility with the specific lubricants and operating conditions of your machinery to maximize lifespan and performance. Factors such as temperature extremes, chemical exposure, and mechanical wear should also be evaluated during the selection process.

Conclusion

In summary, the 20% 35% 7% oil seal is more than just a mechanical component; it is a critical element that assures the smooth functioning of various machines. Understanding its composition and functionality can guide you in making informed decisions about maintenance and replacements, ultimately leading to more efficient and sustainable operations. As industries continue to evolve and innovate, maintaining the integrity of machinery through effective sealing solutions like the 20% 35% 7% oil seal will remain paramount in achieving operational excellence.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories