1 月 . 16, 2025 01:32 Back to list

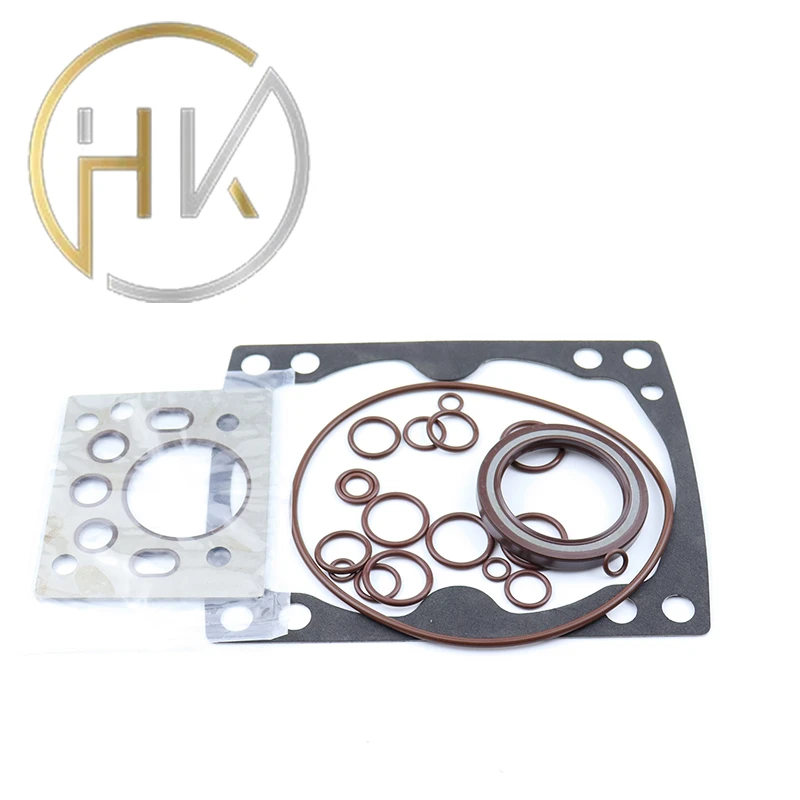

14x28x7 oil seal

The authority in the domain of oil seals is not just about producing these components but also about advancing technological innovations that further enhance their functionality. With the rise of Industry 4.0, where machines are becoming smarter and more connected, oil seal manufacturers are experimenting with materials and designs that can maximize efficiency and reduce energy consumption. Features like reduced friction designs and self-lubricating materials are emerging to meet the next generation of industrial needs, ensuring that machinery runs smoother and with minimal intervention. Trustworthiness in the context of oil seals is multifaceted. It encompasses the reliability of the product in operation, the accuracy of its performance specifications, and the customer service provided by the manufacturer. Trust is built over time through consistent product performance and maintaining open lines of communication with users. This relationship is bolstered by warranties and after-sales support that many reputable manufacturers offer, safeguarding the user's investment. In conclusion, the 14x28x7 oil seal is more than just a mechanical component; it is a testament to industrial precision and reliability. Through experience, expertise, authority, and trust, this small yet significant item safeguards countless machines, helping industries to thrive and innovate without pause. As advancements continue, these seals will undoubtedly evolve, further cementing their place as indispensable in the realm of mechanical engineering.

-

The Power of Advanced Sealing: High-Pressure Solutions for Modern Machinery

NewsOct.29,2024

-

Optimizing Machinery with High-Performance Oil Seals

NewsOct.29,2024

-

Maximizing Machinery Efficiency with Advanced Oil Seals

NewsOct.29,2024

-

Ensuring Equipment Longevity with Quality Oil Seals

NewsOct.29,2024

-

Enhance Equipment Performance with Quality Oil Seals

NewsOct.29,2024

-

Custom Oil Seals for Specialized Machinery Needs

NewsOct.29,2024

-

The Role of Wiper Seals in Dust Sealing and Oil Protection

NewsOct.20,2024

Products categories